Choosing the right ply tires for off-road adventures can significantly enhance your full-sized truck’s performance and durability. As any off-road enthusiast knows, the tires are the groundwork of your vehicle; they bear the weight of heavy load, navigate challenging terrains, and ensure safety while tackling extreme conditions. This article delves deeply into the intricacies of ply tires, highlighting the importance of 10-ply and higher tires for full-sized trucks venturing into rugged terrains. Each chapter will explore vital aspects including structural benefits, performance comparisons between 10-ply and 12-ply options, the critical role of tire materials, and essential maintenance tips to keep your tires in peak condition. Let’s gear up and dive into the world of tread and traction, equipping you with the knowledge to conquer any off-road landscape.

Beyond the Ply: Mastering 10-Ply and Higher Tires for Full-Sized Truck Off-Roading

Choosing the right tires for a full-sized pickup when you plan to venture off the beaten path is a decision that blends engineering, terrain knowledge, and practical risk management. The ply count of a tire—commonly spoken of as a number like 10-ply—has long been a shorthand for durability and load-carrying capacity. In real-world off-road use, however, that number is only part of the story. A tire’s ability to withstand rugged terrain, support a heavy axle load, and maintain a stable footprint under challenging conditions comes from a combination of carcass construction, sidewall design, tread pattern, and the tire’s overall load range. For many full-sized trucks that see serious off-road duty, a 10-ply tire or higher is a common baseline, but the value of that rating rests on how well the tire is matched to the vehicle and the terrain you intend to conquer.

The traditional idea behind a higher ply count is straightforward: more layers equals a stiffer, stronger carcass that resists punctures and can support heavier loads. In practice, this means a tire built with multiple layers of high-strength fabric and sometimes steel in the casing, arranged to distribute load and absorb impacts from rocks, roots, or unpredictable ruts. Off-road environments—rocky trails, sharp shale, or sand-choked washes—place unusual demands on the tire’s structure. A ten-ply or higher tire often provides a generous margin against sidewall punctures and bead failures, which are the kinds of failures that can strand you in remote terrain. Yet durability alone does not guarantee success. The same stiffness that helps resist punctures can translate into a harsher ride and altered handling on pavement. The trade-off is real: with a heavier, stiffer tire, steering feel and braking response can change, and fuel economy may dip. Those considerations lead to a central practical point: the ply rating should be viewed in the context of load range, vehicle weight, and the axle configuration of your truck.

In modern tire specifications, the notion of ply count is closely tied to the concept of load range. A tire described as 10-ply does not automatically deliver ten layers in every construction; rather, it signals a heavy-duty building intended to carry substantial weight. For full-sized trucks, many off-road tires use what is labeled as LT (Light Truck) construction, which denotes enhanced load capacity while preserving intended on-road drivability. The critical insight is to pair the tire’s load range with your truck’s axle weight and suspension geometry. If the weight of your payload, gear, and trailer pushes the axle toward the upper end of the tire’s load rating, a higher ply or reinforced construction can help maintain stable air pressure, avoid excessive deflection, and resist premature sidewall fatigue. Conversely, if the vehicle is lightly loaded or the tires are not matched to the suspension’s travel characteristics, you may not gain the expected advantages from a higher ply count.

Terrain is another essential piece of the puzzle. Desert dunes, for instance, often reward tires designed with wider profiles and reinforced sidewalls, where a broad footprint helps distribute weight and reduce sinkage in soft sand. Mud and loose soil demand tread designs that grip without tearing away the rubber, while rocky terrain tests sidewall integrity and the carcass’s ability to resist punctures from sharp ledges. In many desert-focused or extreme off-road scenarios, tires that are explicitly built for rugged environments incorporate additional layers for puncture resistance and a carcass that maintains stability under high load and low-speed traction. This is where the ply rating becomes part of a broader strategy: selecting a high-ply tire with a construction designed to handle the expected terrain, rather than chasing a higher number for its own sake.

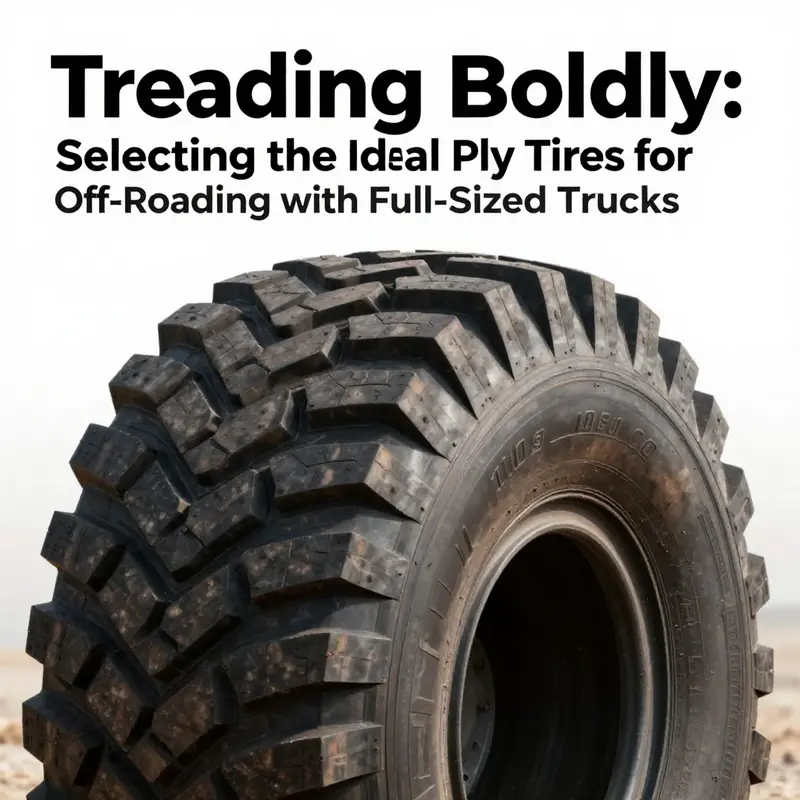

The construction details matter as well. A robust 10-ply or higher tire often features a multi-ply carcass arranged in a cross-plied or radial pattern, sometimes with steel belts or robust cord materials to resist shard-like punctures and keep the tread life predictable. In this context, sidewall architecture becomes equally important. A reinforced sidewall design helps resist pinch flats and scuffs from rocks, while still allowing some compliance for moderate off-road suspension travel. The tire’s bead area, shoulder blocks, and the tire’s overall bead angle play roles in how well the tire maintains a seal against the rim, particularly at low pressures used to maximize flotation over sand or soft mud. A tire built for extreme terrain often blends a thick, puncture-resistant belt, a flexible but strong sidewall, and a tread compound that remains pliable in desert heat or sub-freezing nights. When you combine these features with a ten-ply or higher designation, you get a tire that stands up to harsh conditions without failing in the middle of a long, remote expedition.

But the choice is not simply a matter of stacking ply count. An off-road capable full-sized pickup is a system: axle weight, suspension travel, wheel well clearance, gearing, and even how often you will drive on pavement all inform the best tire choice. A heavy-duty, high-ply tire can alter the vehicle’s effective gear ratio because of increased rolling resistance, and it can change the vehicle’s approach to heat buildup in the tire under sustained off-road crawl or desert heat. Ensuring that the tire is compatible with your truck’s axle weight and suspension geometry is essential. If a truck’s rear axle carries a heavy load or the suspension is tuned for aggressive off-road travel, a higher-ply tire can help maintain traction and stability. If the truck routinely travels long highway legs at speed, the heavier tire may demand slower acceleration, slightly altered braking performance, and attentive tire pressures to preserve the tread’s life and the overall ride quality.

Tire selection for off-road use also benefits from categorization beyond ply. The tread design you choose should reflect the terrain you’ll encounter more often. Mud-terrain tires, with aggressive voids and thick shoulder blocks, can deliver superb traction in sticky clay or loose soil, but often at the cost of higher noise and slightly reduced on-road ride comfort. All-terrain designs aim for a balance of on-road civility and off-road capability, but their durability under extreme conditions may vary widely. When paired with a high-ply carcass, these tread choices can yield strong overall performance, provided the carcass remains within the vehicle’s load and handling envelope. The lesson is simple: match the tire’s construction and tread philosophy to the terrain mix you expect, and then confirm your vehicle’s suspension, wheel wells, and drivetrain tolerances align with that choice.

A common source of confusion is how tire size interacts with height, width, and the vehicle’s clearance. Ten-ply or higher tires are often paired with larger diameters or wider footprints in the off-road category, but any increase in tire size must be checked against fender clearance, steering lock, and axle articulation. Elevating the tire can also affect the vehicle’s effective gearing, particularly if you are operating at lower speeds with substantial torque, as is typical in off-road climbs. The practical approach is to select a tire size that accommodates the vehicle’s clearance and suspension travel, and then confirm that the tire’s load range and ply rating are sufficient for the anticipated payload. If you lift the truck to gain ground clearance, you may unlock more tire options, but you also introduce new mechanical and steering considerations—components that must be evaluated together with the tire choice to prevent rubbing, heat buildup, or excessive wear.

In the end, the choice of a 10-ply or higher tire for a full-sized truck off road is a decision that hinges on purpose and balance. You may find that a desert-focused, puncture-resistant tire with reinforced sidewalls and a broad footprint performs best for dune runs and long, sandy corridors, while a rugged mud-terrain design might excel on a rocky, clay-logged trail where mud is the main adversary and rocks are encountered less frequently. The key is to align the tire’s carcass construction, sidewall strength, and tread philosophy with your vehicle’s load profile and the terrain you intend to conquer, then verify that the wheel, suspension, and axles can accommodate the combination without compromising safety or reliability. That alignment—tire, vehicle, terrain, and technique—transforms a heavy, off-road-ready rig from a project into a trusted companion on daily drives and remote expeditions alike.

For readers seeking deeper technical grounding on tire standards, properties, and practical applications, a comprehensive technical guide offers nuanced perspectives on sizes, construction, and performance in demanding environments. External resource: https://www.ural-truck-tire.com/technical-guide

Understanding the Structural Benefits of 10-Ply Tires for Full-Size Trucks Off Road

When a full-sized pickup leaves the pavement and heads into rugged terrain, the tires do more than carry the vehicle. They are a core part of load handling, impact resistance, traction, and the ability to stay productive through long hours of work. This chapter explains why a 10-ply or higher designation matters for full-size trucks, how that structure translates into real world performance, and what trade-offs come with rugged casings.

The 10-ply label points to a redesigned approach to tire construction that emphasizes strength and durability without totally sacrificing ride or efficiency. Modern off-road tires rely on a carefully engineered combination of high strength fabrics, steel belts, and advanced polymers that create a rigid sidewall and a resilient carcass. The result is a tire that resists puncture and deformation when confronted with rocks, roots, and the punishment of off road travel. Sidewalls become a focal point of durability because they carry part of the impact energy and help prevent rapid air loss, keeping the wheel and suspension safer.

These structural benefits extend beyond puncture resistance. A reinforced carcass supports higher load capacities, which matters for full-sized trucks that haul gear, equipment, or heavy cargo over rough routes. In off road work, payload includes gear, recovery equipment, winches, fuel, and obstacles encountered along the way. Tires with robust construction distribute load across a larger contact patch, improving stability and reducing bead unseating or carcass failure when the terrain shifts. That stability translates into more confident steering, better braking, and steadier handling on ruts and rocks.

Traction on off road surfaces is about more than grip. A well designed 10-ply tire maintains its shape under throttle and cornering on dirt, mud, sand, or loose gravel. The combination of a reinforced casing and an aggressive tread helps bite without excessive squirm. This aids control on off camber slopes and when balancing torque with terrain features. The same casing also helps resist damage from hidden objects and wet surfaces, turning a potential puncture path into a tough but forgiving ride that still performs when conditions demand more from the tire.

A key benefit is wear behavior. A robust construction often yields more even wear and longer tread life under demanding use. When wear stays even, the tire remains in contact with the ground for longer portions of its life, preserving traction and predictable handling. For trucks that run long shifts on rough ground, durability reduces downtime for maintenance and lowers the frequency of tire changes, contributing to lower life cycle costs.

Trade offs include added weight and its effects. Heavier tires raise unsprung weight, which can influence ride quality, steering feel, and acceleration. They also interact with fuel economy and wear patterns on suspension components. For highway duty with occasional off road work, the right balance is essential. The stiffer sidewalls needed for rough terrain can feel harsher on smooth roads, and higher rolling resistance or noise may accompany the design. The best choice depends on the vehicle mission profile, not just the biggest number on the sidewall.

When selecting 10-ply tires, start with a clear view of the vehicle mission. If off road work is frequent and the terrain is rocky, the rugged casing is a real asset. If most driving is highway with occasional off road detours, a more nuanced design may provide a better blend of durability and comfort. The 10-ply label signals a design philosophy focused on resilience, load distribution, and reliable performance under heavy use.

Maintenance and inflation are still essential. A stiff casing shows its strength only when run at proper pressures for load and speed. Regular inspections for cuts, bulges, and bead seating matter, and rotations and alignments help prevent uneven wear. The 10-ply advantage is most meaningful when you respect terrain and drive with measured speed and caution rather than trying to overpower the surface.

In sum, 10-ply tires for full sized trucks off road offer high load capacity, resilience, and traction in demanding environments. They are a practical choice for trucks that haul heavy payloads across rough landscapes, where puncture resistance and stable geometry can mean the difference between progress and downtime. For deeper, manufacturer backed specifications and testing methodologies, consult the official guides provided by tire makers. External resource: https://www.michelin.com/en-in/tyres/truck-tyres

Performance Comparison: 10-Ply vs. 12-Ply Tires for Off Road Full Sized Trucks

When a full-sized pickup leaves the pavement and enters a world of rock, mud, sand, and steep grades, the choice of tire construction matters as much as the engine or the suspension. Ply rating—not just tread pattern or tire width—shapes how a tire behaves under load, in sharp objects, and at the limits of grip. The decision between 10-ply and 12-ply tires is not a simple matter of which is tougher; it is a trade-off between load capacity, durability, ride quality, and how aggressively you intend to attack extreme terrain. Read through the lens of a practical off-road workflow, and the contrast between these two common ply levels becomes a guide to matching tires to purpose. A heavy-duty field scenario, such as towing, hauling rough equipment, or negotiating stony trails with a loaded truck, benefits from the amplified stiffness and puncture resistance of higher ply tires. Yet for many mixed-use rigs—a daily driver that spends weekends in the boonies—the 10-ply option often offers a more balanced blend of capability and comfort. The distinction starts with the tire’s core structure: multiple layers of fabric and sometimes steel, stacked in a crosshatched arrangement to distribute impact forces and resist punctures. A 12-ply tire, with more plies backing the bead and sidewall, presents a thicker barrier that can absorb a heavier share of abuse before a puncture translates into a failure. That extra protection matters most when the terrain throws up sharp rocks, tree stumps, or abrasive desert surfaces that threaten sidewalls and shoulder blocks. In practical terms, a 12-ply tire carries more load per tire and preserves its integrity under stress, which translates into higher confidence when you’re towing a heavy trailer across uneven grades or deep ruts. The cushion behind the tread is stiffer, and this stiffness is not simply about strength; it also translates into a predictable response when landing a heavy impact or bumping into a rock ledge at speed. For drivers who routinely operate under heavy use conditions, the 12-ply design tends to hold its line better, resisting deformation that could lead to bead seating issues or bead slip during a high-load ascent. But there is a cost to that rigidity. The same multi-ply architecture that resists punctures and maintains shape also tends to increase the overall weight of the tire. Heftier tires mean more unsprung weight, and that has a chain reaction through the vehicle’s dynamics: more inertia when turning, more momentum to overcome on steep climbs, and a stiffer interface with the suspension, which can translate into a harsher ride on rough roads. On the highway, where miles accumulate and the tires aren’t welcome guests of the pavement’s roughest days, the effect becomes more noticeable. The stiffer sidewalls of a 12-ply tire reduce the tire’s ability to absorb minor pavement imperfections, translating into a firmer ride and more tire noise. That firmness, however, brings a compensating advantage in stability. When a heavy trailer is attached, the stiffer sidewalls resist sideways movement and trailer sway. The steering feel is more deliberate, which can translate into improved control at the limit on loose surfaces or in crosswinds. The trade-off is not purely subjective—it’s measurable in how the tire behaves across the spectrum of terrain: from soft mud to jagged rock and baked sand. The interplay between ply count and tread design becomes especially important on rock-strewn courses where sidewall integrity is tested as much as the tread’s bite. A 12-ply sidewall can resist pinching and pinhole punctures that would otherwise fold a thinner alternative when rocks press against the tire’s flank. The risk of bead damage in a high-angle climb or a drop onto a granite platform is reduced, which keeps the tire in service longer and reduces the likelihood of a roadside repair under harsh conditions. Yet this is not a universal blessing. In situations where the surface is less punishing but conditions demand quick maneuverability, the 10-ply tire often performs more gracefully. The slightly more compliant sidewalls and lower overall weight tend to yield a smoother ride on paved roads and certain mixed-terrain courses. They also reduce rolling resistance, which can translate into better fuel economy and less fatigue on long highway stints. For enthusiasts who blend trail days with everyday commutes, the 10-ply option frequently emerges as a sensible compromise that does not demand sacrificing daily comfort for weekend grit. The design science behind these numbers matters as well. The ply count is not the sole determinant of durability; the quality of the cord material, the way plies are layered, and the inclusion of additional reinforcing fibers or steel belts all shape the tire’s performance envelope. With a higher ply rating, manufacturers often incorporate more robust sidewall compounds and stiffer bead assemblies, contributing to fewer deformations under load and stronger resistance to cuts or punctures from sharp objects. In severe off-road conditions, such as rock crawling or deep desert sand where rocks and glass are common, the benefit of a higher ply becomes more apparent. There, the risk of sidewall injuries and bead failures can end a trip early. The 12-ply tire’s extra margin in this region translates to longer legibility of the tire’s tread life and more predictable traction in the presence of puncture threats. But there is more to consider than just the tire itself. The vehicle’s chassis, suspension geometry, and the choice of wheel offset can influence how a given ply rating performs in the real world. A vehicle with a high center of gravity and a stiff spring setup may feel the bite of a 12-ply tire more acutely, while a well-tuned suspension can exploit the rigidity to improve handling and payload stability. Conversely, on a vehicle with a long travel suspension or soft ride feel, a 10-ply tire can provide welcome compliance without sacrificing too much in the way of durability, thanks to modern tire construction that balances load-carrying capacity with heat dissipation and load distribution. This balance is where the decision often lands for owners of full-sized trucks who regularly traverse mixed terrain. If you routinely haul heavy loads, tow significant trailers, or work in environments where rock faces, thorny brush, and abrasive soils are the norm, the 12-ply option stands out as the safer bet. Its ability to sustain higher loads per tire minimizes the risk of failure under heavy load and extreme impact, and its puncture resistance lowers the likelihood of a roadside mishap. If your routine is a blend of highway cruising, camping trips, and occasional off-road forays, the 10-ply option can provide a more comfortable ride without surrendering too much in the way of off-road capability. It also tends to be more economical upfront and over time, thanks to lighter weight and lower rolling resistance. In this context, tire choice becomes a reflection of priorities rather than a universal rule. To navigate these priorities, you might start with an honest appraisal of how you use the truck. Consider how often you trailer or haul heavy loads, how frequently you navigate demanding terrain, and how much highway time you log. If the answer tilts toward heavy-duty work, mud-rich or rock-laden trails, and long, loaded climbs, the 12-ply option offers clear advantages in durability and confidence. If the work is lighter, or you value ride quality and efficiency on paved roads with occasional forays into the rough, the 10-ply choice provides a comfortable, capable compromise. It is worth noting that the language around ply ratings can be nuanced. The formal rating is about load-bearing capability and structural redundancy, but the practical experience also depends on tire construction details—such as the cord material, layering scheme, reinforcement compounds, bead design, and the tread’s geometry. A 12-ply tire with a balanced, modern construction can outperform an older or poorly designed 10-ply model on the same terrain. The reverse can also be true when a 10-ply tire is engineered with cutting-edge materials and a robust sidewall profile that favors digesting hits without sacrificing performance elsewhere. For the reader who wants a deeper, side-by-side understanding, turn to independent performance guides that synthesize field testing with manufacturer data. They provide real-world numbers on load capacity, puncture resistance, and heat buildup, alongside ride quality assessments across varied terrains. The discipline of tire selection for off-road full-sized trucks is not about chasing the maximum rating in every category; it is about aligning the tire’s strengths with the vehicle’s behavior and the user’s priorities. If you anticipate frequent heavy-duty use, the extra margin in a 12-ply tire is a hedge against failure and an ally in stability. If comfort, efficiency, and versatility take precedence, the 10-ply option can still deliver impressive off-road chops without imposing the penalties that come with maximum ply counts. For a practical synthesis of specifications and tested outcomes, consider consulting a detailed, independent performance guide that compares 12-ply and 10-ply tires in off-road contexts. It provides a grounded view of how these ratings translate into real-world results, helping readers calibrate expectations with their own driving patterns. As you weigh these choices, remember that tire life is a function of driving style, maintenance, and terrain, not ply rating alone. Regular inspection, proper inflation, and correct mounting practices remain essential. A higher ply tire is not a license to neglect care; it is, rather, a tool whose value unfolds when paired with attentive operation and sensible loading. For readers who want to explore related mechanical considerations beyond tires, see this practical guide on diesel systems and the interplay between drivetrain load, suspension dynamics, and tire behavior: Mastering diesel mechanics: a step-by-step path to success. For a broader, external reference that consolidates contemporary data on ply comparisons, consult the following comprehensive resource: https://www.trucktirepro.com/12-ply-vs-10-ply-tire-performance-guide.

Layered Strength on the Trail: How Tire Material Defines Off-Road Performance for Full-Size Trucks

When a full-size pickup heads into mud, rock, or sand, the tires do more than keep the wheels turning. They translate effort into traction, protect the wheel and suspension from harm, and govern how a vehicle carries weight in the rough. The material that makes up the tire—the rubber compound, the reinforcing plies, the fillers that give it stiffness or flexibility—plays a decisive role in off-road capability. This chapter pulls back the curtain on tire material, explaining how different compounds and constructions interact with terrain to deliver grip, durability, and resilience. It also threads a practical line through the trade-offs factory and aftermarket tires must manage, so drivers know what matters when they choose a tire for true off-road duty on a full-size truck.

Traction on slippery or uneven surfaces begins in the rubber itself. The material must grip loose rock, wet clay, sand, and dry dirt, yet still conform to irregularities in the ground so the tread can bite. In this sense, high-silica compounds often take center stage for off-road performance. Silica enriches the elastic network of the rubber, enhancing grip on loose substrates without making the compound so stiff that it becomes brittle in sharp cornering. The weight of a full-size truck compounds this need: a heavy vehicle requires materials that can maintain contact pressure under load, resisting squirm and slippage when the terrain suddenly shifts under the tire. The result is predictable, confident acceleration and braking in environments where the ground can change from smooth to jagged in a few feet. Yet traction is not a single property of the compound alone. It is the interaction between the compound and the tire’s structure—the way the belt, carcass, and sidewall respond under load—that ultimately determines how much grip is available when it matters most.

Durability is equally material-driven, especially for full-size trucks designed to haul, tow, or crawl through rough terrain. Off-road surfaces are unforgiving; thorns, shale, and embedded rocks threaten to cut a tire’s sidewall or nick the tread. Here, the reinforcing layers—often multiple plies laid in specific orientations—form a kind of protective armor. For heavy, off-road-focused tires, manufacturers lean toward reinforced sidewalls and thicker plies that resist punctures and sidewall deformation when the tire brushes a rock ledge or drops into a rut. The ply count matters because each added layer spreads load more evenly and resists puncture when the tire experiences high contact stress. In practice, a 10-ply or higher construction provides a stiffer tire that stands up to sharp terrain and heavy loads, reducing the risk of rapid air loss or bead damage. The trade-off, of course, is weight and potentially a stiffer ride. But for vehicles that regularly push into rough terrain, that stiffness is a cost worth paying to protect the tread area and the wheel beneath.

Resistance to damage blends the material science with engineering design. Off-road tires face cuts, bruises, and chipped edges, particularly when a vehicle rocks over jagged rocks or drives through debris-strewn trails. The solution is a combined package—an aggressive tread with robust, cut-resistant compounds and a carcass designed to cap the edge of any puncture or crack. The treads themselves reassert control here: deeper lugs that are tall enough to grip without folding into themselves when the tire is deflated, paired with a compound that resists chunking at the base of each lug. Self-cleaning tread patterns, which shed mud and debris rather than packing it, rely on the material’s flexibility at low temperatures and the overall tread geometry to maintain contact with the ground. When mud builds up, a tire must still bite; the right material ensures the lug remains pliable enough to maximize surface contact while resisting tearing under lateral impacts or when rocks strike the tread from the side.

The balance of properties—grip, durability, and damage resistance—must be tuned for the conditions a full-size pickup is likely to encounter. A softer compound may deliver superior traction on slick surfaces and loose soils, but it wears quickly on pavement and declines more rapidly in heat. A harder compound can last longer on the highway but often sacrifices the sidewall flexibility needed for predictable behavior on rough terrain. This balancing act becomes even more crucial when the tires are paired with a high-ply construction. The increased ply count contributes to sidewall stiffness and payload capability, helping the tire maintain its shape under load and resist punctures, yet it can also raise rolling resistance and reduce ride comfort if the carcass becomes too rigid for highway use. For many owners who use their trucks as daily drivers with occasional off-road excursions, the choice is not simply about finding a tire that can crawl over rocks. It is about selecting a material and ply architecture that preserve on-road manners while still delivering the off-road resolve required on weekends.

The decision to opt for a 10-ply or higher tire is more than a nod to rugged aesthetics. It reflects a specific engineering approach to the demands of full-size trucks on varied terrain. Higher ply counts enable higher load ratings and improved resistance to puncture and bead damage, which is especially valuable when a vehicle is carrying heavy gear, towing a trailer, or navigating rugged trails with uneven weight distribution. The extra layers distribute stress over a larger area and reduce the likelihood that a single impact will lead to a catastrophic failure. At the same time, the thicker construction tends to reduce the tire’s overall compliance, which can dull small shocks and make the ride feel harsher on paved surfaces. This is not a defect so much as a sensible trade-off: the tire is optimized for the conditions it’s most likely to encounter. For many off-road enthusiasts, the payoff is straightforward—greater confidence when the ground turns technical and an ability to absorb impacts that would otherwise crack a less robust sidewall.

A tire’s material story does not end with the rubber and the plies. The infill materials, the bond between layers, and even the resin systems used in manufacturing influence performance in subtle but meaningful ways. Temperature management becomes more critical with heavy-duty compounds. On long, exposed climbs or desert crossings, heat can build up in the tire, softening the compound and reducing stiffness at the point where the tread meets the ground. A well-chosen material system maintains grip across a broader temperature range, ensuring that the tire remains predictable as the sun climbs higher and the ground heats up. When a truck is laden with gear or is pressing through a washboard section, the ability of the material to rebound from deformation defines the continuity of traction. In each case, engineers aim for a tire that holds steady contact with the terrain while resisting deformation that would break contact and compromise grip.

For drivers weighing the realities of off-road life, the material choice becomes a practical lens through which to view performance. Rigid, puncture-resistant tires with reinforced sidewalls deliver peace of mind when the trail suddenly narrows to rock and gravel. On the other hand, a softer, more flexible compound with a slightly lighter ply count can deliver smoother ride quality and better grip on mud, as long as the terrain does not demand the outer shell’s maximum resilience. The best approach is to align the tire’s material characteristics with the driver’s typical terrain, load, and road use. If the mission profile emphasizes steep climbs, heavy loads, and rock gardens, a tire built around a 10-ply or higher architecture with a robust silica-rich compound will often outperform a lighter setup in the same conditions. If the vehicle spends most of its miles on pavement but still encounters seasonal off-road trails, a balanced option with a moderate ply count and a compound tuned for mixed terrain can deliver acceptable tread life with sufficient on-trail traction.

This discussion also touches the broader ecosystem of maintenance and usage habits. Tire material cannot work in isolation from inflation pressure, rotation cadence, or cargo weight, all of which influence how the material behaves under load. Proper inflation helps the tire maintain its intended footprint and prevents undue stress on sidewalls, an essential factor when the tire’s material is already working at the extremes of its design envelope. Regular rotations prevent uneven wear that can reveal a mismatch between trail demand and material capabilities. In practice, the synergy between material choice and maintenance practices often dictates whether the tire’s advantages translate into real-world performance or remain theoretical. A tire with a robust 10-ply design and advanced compounds deserves not just appropriate ride height and suspension tuning, but a disciplined maintenance routine that keeps pressure within the recommended range and ensures even wear across the tread surface.

For readers seeking a broader contextual understanding of tire material composition and how standards shape real-world application, a comprehensive reference on material composition and technical standards offers deeper insight. It can help translate the nuanced trade-offs described here into concrete selection criteria for a given truck, workload, and terrain. See the wider discussion in the external resource detailed at the end of this chapter for a more technical treatment of material science in off-road tires. Additionally, a related practical narrative on equipment maintenance and diesel mechanics provides context for how drive-train components interact with tires during demanding off-road exploits, reinforcing the idea that tire success rests on a holistic approach to vehicle readiness. Mastering Diesel Mechanics: Your Step-by-Step Path to Success.

In sum, tire material for off-road full-size trucks is a carefully engineered ecosystem. The compound chemistry, the reinforcement strategy, and the interaction with tread geometry all converge to deliver traction, durability, and resistance to damage. The 10-ply or higher configurations, in particular, embody a design philosophy that prizes load-bearing resilience and puncture resistance, essential for serious off-road work. Yet even within this robust framework, the practical choice depends on how you plan to balance on-road comfort with off-road capability, and how much weight you expect to carry on the trail. The material story matters not as a standalone feature but as a core element of a broader strategy to keep the vehicle mobile, predictable, and safe when the ground refuses to be flat. For drivers who intend to venture beyond the pavement with regularity, investing in tires that emphasize layered strength—through both robust compounds and reinforced constructions—offers a tangible pathway to more confident, capable off-road performance.

External reference for a deeper dive into material composition and standards: Mudding Tires For Trucks: Material Composition, Technical Standards, and Common Applications. https://www.tirebloc.com/blog/mudding-tires-for-trucks-material-composition-technical-standards-and-common-applications

Rugged Care: Maintaining 10‑Ply and Heavier Tires for Full‑Size Truck Off‑Road Use

Off-road use subjects full-size trucks and their tires to forces and hazards that demand a maintenance approach built around prevention, careful inspection, and smart handling. When you choose 10-ply or heavier tires for a full-size pickup, you gain superior load capacity, puncture resistance, and puncture mitigation thanks to multiple cord layers and beefed-up sidewalls. Those strengths also change how the tires behave and what they need to stay reliable. This chapter walks through the practical, day-to-day care required to preserve performance, extend life, and reduce the risk of failure while off-roading.

Start with a disciplined inspection routine. Before any trip, walk around the truck and look for cuts, bulges, sidewall abrasions, embedded rocks, or foreign objects lodged in the tread. After a run, repeat the check. Small punctures can be sealed by the tire’s multi-layer construction and not show immediate air loss; however, driving on a compromised tire risks sudden failure. Pay special attention to the sidewalls. Thicker sidewalls on 10‑ply tires handle impacts better, but they are not invincible. Rips, separations, or cords showing through the rubber indicate the tire needs repair or replacement. Keep a small mirror and an LED flashlight in the truck so you can inspect hard-to-see areas quickly, and learn to recognize abnormal wear patterns that hint at underlying issues such as alignment problems, suspension stress, or incorrect inflation.

Tire pressure is a central variable for off-road success and tire longevity. Lowering pressure increases the contact patch, improving traction on sand, mud, and rocky trails and reducing the tendency to roll on rutted ground. But heavy 10-ply tires can support greater loads at higher pressures, so dropping pressure too far under heavy loads risks rim damage when you hit a rock or drop into a hole. Establish a pressure plan for different surfaces and loads: a moderate reduction for soft dirt, a slightly lower setting for deep sand runs, and near-factory pressures for long highway travel or heavy towing. Use a reliable digital gauge and a portable compressor so you can reinflate at camp or a trailhead. Monitor pressure changes during a run; heat buildup from slow speeds or prolonged heavy work raises internal temperatures and pressure, and repeated heating cycles accelerate wear.

Rotation and balancing deserve attention often overlooked with off-road focus. Regular rotation evens tread wear across all tires and helps retain the balanced ride that reduces strain on wheel bearings and suspension. For directional or staggered setups, follow a rotation pattern recommended for your tire type, and measure tread depth across the width and around the circumference to spot cupping or feathering early. Balancing reduces vibration that can loosen lug nuts or stress chassis components. After a season of aggressive off-roading, rebalancing is often warranted; imbalance can develop from repeated impacts that deform the tire’s structure, even if no visible damage exists.

Sidewall protection strategies minimize downtime and expensive repairs. Many dedicated off-roaders add beadlock-style protection or reinforced inner liners to limit rim damage and prevent bead separation when airing down. Beadlocks must be installed and torqued correctly; improper use causes wheel damage. Keeping a quality tire plug kit, a compact impact tool or torque wrench, and a spare heavy-duty wheel and tire is prudent. If a puncture occurs in the tread area, a repaired 10-ply tire can often be returned to service if the repair follows industry standards and is done from the inside using a combination plug/patch. Sidewall repairs are more limited and often unsafe to attempt; if a sidewall is compromised, replace the tire.

Cleaning and debris management preserve compound flexibility and prevent long-term damage. After harsh runs, wash away mud, salt, chemicals, and fine gravel from tread and wheel wells. Letting corrosive substances sit shortens tire and wheel life and accelerates suspension rust. Avoid aggressive solvents that can degrade rubber compounds; use mild soap, water, and a soft brush. When storing vehicles or spare tires between outings, keep them out of direct sunlight and away from heat sources to minimize UV and ozone-related cracking. Rotate storage positions so tires do not sit under heavy loads indefinitely; resting a heavy truck on the same tires for months can create flat spotting.

Adjust maintenance to match how the truck is used. If the vehicle tows heavy trailers or regularly carries heavy payloads, inspect the tires more often and maintain pressures closer to the higher end of the safe range. Those who run technical rock trails should emphasize sidewall inspections and consider supplements like rock rings or reinforced rims. Drivers who mainly cross sand should monitor tread wear from abrasive conditions and avoid sudden, sustained engine braking that can overheat tires. Keep a log of mileage, pressures used, terrain types, and any repairs. Over time, that record will reveal patterns and help you predict when tires will reach service limits.

Safety equipment and emergency preparedness matter as much as routine care. Carry spare valve stems, a heavy-duty jack appropriate for a full-size truck, and a wheel chock. Use a high-quality tire plug kit and a compatible sealant, but view sealant as a temporary fix until a proper repair can be made. When changing a tire on uneven ground, ensure the vehicle is securely braced and stabilized; the higher weight and stiffer sidewalls of 10‑ply tires increase the difficulty of wheel removal. Train crew members on safe jack points and on proper lug nut torque values to prevent warped rotors or loose wheels.

Follow manufacturer recommendations for mounting, demounting, and storage. Tire makers publish load tables and inflation charts tied to ply ratings and tire sizes. Those guidelines reflect the complex interaction between load, pressure, and temperature and are a reliable baseline. For technical questions or suspect damage, consult a qualified tire technician. Many problems that start small—bead separation, internal belt shifts, or slow leaks—are best addressed early by professionals who can dismount and inspect the internal construction.

Finally, consider a preventive mindset: treat maintenance as part of every outing, not an occasional chore. A disciplined routine of inspection, correct inflation, timely rotation and balancing, careful cleaning, and carrying the right tools will keep 10-ply and heavier tires delivering their advantages in traction and durability. That approach reduces surprises on the trail, lowers long-term costs, and preserves the safety margin that heavy-duty ply tires are intended to provide.

For detailed technical guidance on testing and standards related to heavy ply tires and off-road stresses, refer to industry technical publications for the latest research and recommendations: https://www.sae.org/publications/technical-papers/content/2023-01-0956/.

For fleet operators or those who manage multiple trucks, investing in staff training and preventive maintenance programs makes a big difference. Learn more about building a people-first maintenance culture and fleet readiness in practical fleet management resources such as this discussion on investing in people and fleet success: https://dirtantrucks.com/invest-in-people-key-to-fleet-management-success/.

Final thoughts

The journey into the world of ply tires for full-sized trucks reveals essential truths that every off-road enthusiast must embrace. Selecting the right ply tires, especially opting for 10-ply or greater, can transform your driving experience in unpredictable terrains. Understanding the structural benefits, comparing performance between 10-ply and 12-ply tires, exploring the materials at play, and implementing steady maintenance practices will bolster your truck’s capability and lifespan on rugged adventures. As you venture deeper into the wild, let the reliability of your tires pave the way. Equip yourself wisely and prepare to conquer whatever nature throws your way.