Off-road trucks embody the spirit of adventure and resilience, purposefully designed to tackle the earth’s most unforgiving terrains. For off-road enthusiasts, adventurers, and competitors alike, these muscular vehicles represent not just a mode of transportation, but the bridge between civilization and the wild. This article delves deep into the defining features that make off-road trucks stand out, the extensive applications where they prove their worth, and sharp contrasts with regular vehicles that simply cannot endure such harsh environments. Together, we will uncover why off-road trucks resonate with those who seek thrill, exploration, and rugged reliability.

Rugged Machines for Hard Terrain: Key Features That Define Off-Road Trucks

Off-road trucks occupy a distinct niche in the world of transportation. They are not ordinary highway vehicles designed for comfort and efficiency on paved streets. Instead, they are purpose-built machines that must perform reliably where road surfaces vanish and obstacles multiply. In deserts where sand sifts beneath the chassis and rocks bite at undercarriages, in forests where roots threaten to trip a tire, or on steep, uneven grades that demand steady throttle, an off-road truck must deliver a blend of power, protection, and control. The idea behind these trucks is straightforward: maximize mobility and payload capacity while preserving the ability to traverse terrain that would stall a standard pickup or a typical heavy-duty truck. The resulting machinery is a study in rugged engineering, where every component is chosen not for luxury but for resilience and predictable performance under the harshest conditions. The best way to understand what an off-road truck means is to imagine a vehicle that can both haul a heavy load across a remote work site and keep moving when the terrain turns hostile. It is a vehicle that balances brute strength with carefully tuned systems that manage heat, grip, and stability. In effect, off-road trucks are mobile platforms designed to operate where the pavement ends and the challenge begins, and that contrast—between the safety net of a highway and the raw demands of remote work—drives their most critical design choices.

At the core of every off-road truck lies a belief in power tuned for torque as much as speed. Heavy-duty powertrains are the heartbeat of the platform. These are not delicate engines built for quiet highway miles; they are robust powerplants capable of delivering sustained pulling power when a slope rises sharply and a payload presses against the rear. The engines are typically high-capacity V8s or turbo-diesel units that generate strong low-end torque and maintain it through the mid-range. The torque curve matters as much as peak horsepower because it translates to the ability to begin moving from a standstill on loose gravel, to maintain momentum when mud clings to the tires, and to keep a heavy trailer climbing a steep grade without the engine dipping into its efficiency margins. Alongside this, the cooling system is engineered with extra reserve. When a truck labors under load in a desert sun or at an elevated altitude where air is thinner, the cooling system must remove heat from the engine, transmission, and powertrain accessories with ease. That extra cooling capacity is not a luxury; it is a necessity that prevents heat soak, preserves performance, and prolongs engine life in environments where maintenance opportunities are scarce.

The ability to move heavy loads is inseparable from the demand for stability and control. Off-road trucks routinely boast high towing and hauling capacities that are not just about raw numbers but about how those numbers translate to real-world steadiness. In many configurations, class-leading towing capacities exceed 12,000 pounds, a figure that speaks to the vehicle’s design intent: to carry equipment, materials, or oversized payloads through rough terrain without compromising control or safety. These capacities are supported by factory-installed towing packages that include a trailer brake controller to modulate braking force in response to the trailer, sway control systems that limit dynamic roll, and hitch assist that makes it easier to couple and maneuver heavy trailers in challenging conditions. The combination of robust frame integrity and purposeful trailer support ensures that the load remains stable on uneven ground, reducing the risk of jackknifing or sway that could jeopardize a mission in a remote area.

Equally important is the chassis and suspension system, which form the skeleton that keeps the truck upright and responsive when the going gets rough. A reinforced chassis—built to resist bending, twisting, and fatigue under heavy payloads—works in concert with upgraded cooling and a rugged suspension to absorb impacts from rocks, ruts, and sudden changes in surface texture. The suspension is not simply stiffer; it is smarter, often featuring components designed to maintain tire contact with the ground across irregular surfaces. In practice, this translates to better traction and more predictable handling when a wheel drops into a rut or a rock confronts the tire at a sharp angle. The focus on durability here is not only about surviving the immediate obstacle but about preserving the long-term reliability of the truck in environments where a dealership and a full-service shop might be days away.

Advanced off-road capabilities extend beyond brute strength. Traction control systems and locking differentials are the quiet champions of obstacle negotiation. Integrated traction control helps the driver manage wheel spin across dirt, mud, or sand by modulating power and brake application to individual wheels, prioritizing grip where it matters most. Locking differentials, when engaged, force the two or more wheels on an axle to rotate at the same speed, which dramatically improves grip on surfaces with low traction. Combined with a generous ground clearance, these features enable the truck to clear obstacles that would stop a conventional vehicle. The result is a machine that can move with confidence on uneven surfaces, weaving a path through the rough while carrying heavy loads. In practical terms, this means the vehicle can maintain momentum through soft sand, drift over rocky terrain, and scale short, steep pitches without losing control. The interplay among power, grip, and weight distribution is a delicate balance, but when dialed in correctly, it becomes a reliable, repeatable capability rather than a momentary burst of luck.

The necessity for configurable configurations speaks to the varied demands of off-road work. Depending on the intended use—logging, mining, overlanding, or industrial support—the same basic platform can be adapted with different wheel arrangements, axles, and payload configurations. Multi-axle setups, specialized trailers, and distinct cargo classifications (small, medium, large) allow operators to tailor the truck to exact tasks. A logging operation might favor a setup that maximizes stability and traction on steep woodland trails, while a mining site could need an arrangement optimized for haulage across loose regolith and heavy payloads. This adaptability is a hallmark of off-road trucks: they are not a single-purpose machine but a platform that can be reconfigured to address a range of demanding missions while maintaining reliability under continuous load and exposure to the elements.

Alongside mechanical robustness, safety and regulatory compliance play a crucial role. Many off-road trucks are designed with compliance in mind, ensuring that even though they operate far from the nearest road, they still align with highway-grade weight and safety standards when used for long-distance hauling or on mixed-terrain routes. This dual capability—uncompromised off-road performance paired with a level of highway readiness—expands the utility of these vehicles. The durability is not simply about resisting physical abuse; it is also about preserving occupant safety and ensuring that the vehicle can operate in diverse environments without sacrificing critical safety margins.

Maintenance and reliability underpin the practical value of an off-road truck. The engineering choices that enable extraordinary performance at low speed and high torque inevitably demand disciplined upkeep. Regular inspection of chassis mounts, cooling lines, and suspension bushings is essential to catching wear before it becomes a problem in the field. Powertrains that produce high torque must be cooled and lubricated efficiently, with attention to filtration, cooling fan operation, and fuel delivery reliability under heavy load and at altitude. In this context, the maintenance culture around off-road trucks emphasizes proactive checks, robust parts supply, and clear maintenance intervals. For readers who want a structured approach to keeping the core powertrain and drivetrain components in peak condition, resources focused on diesel mechanics and heavy-duty engine upkeep provide practical, step-by-step guidance. Mastering Diesel Mechanics: Your Step-by-Step Path to Success offers a useful framework for maintaining high-torque engines, ensuring cooling systems stay effective, and performing routine inspections that minimize downtime in remote locations.

The portfolio of features across off-road trucks reflects a design philosophy rooted in balance. Engineers aim to equip a vehicle with a robust powertrain that can haul substantial loads, a chassis that can absorb and distribute severe shocks, and a suspension that maintains tire contact and stability on a spectrum of surfaces. They integrate traction-enhancing technologies and differential strategies that allow the truck to climb, traverse, and descend with controlled precision. They also recognize that the mission profile may require specific configurations; thus, the platform supports adaptability without compromising core capabilities. This is why an off-road truck can be deployed on a mining site one day, then serve in a forestry operation the next, and perhaps participate in a rugged field test where engineers evaluate new traction systems or load-management tools. The outcome is a vehicle that remains useful over a long service life, resisting wear from repeated exposure to mud, heat, vibration, and friction.

The broader implication of these features extends beyond the immediate tasks of moving payloads through difficult terrain. Off-road trucks embody a philosophy of resilience—an emphasis on preserving momentum and safety in environments where human access is limited, and the costs of downtime are high. The emphasis on heavy-duty powertrains and reinforced structures translates into a machine that can operate with minimal external support, a crucial factor in remote industrial settings. The ability to tow, haul, and maneuver through challenging terrain means that a single truck can replace multiple lower-capability vehicles, reducing the complexity of a fleet and simplifying logistics. Yet the trade-off remains clear: these vehicles are engineered for practicality over pampering. The interiors, while functional, prioritize durability and serviceability, and fuel economy is a secondary consideration to reliability under demanding conditions.

As readers consider the implications of these features for real-world operations, it is useful to reflect on the connection between design and practice. The off-road truck is not merely a tool for moving materials; it is a mobile platform that embodies a workflow for managing physical challenges. When a crew needs to reach a remote site, set up a temporary work camp, or transport heavy equipment across rough ground, the truck provides the mobility, power, and control required to complete the task. Each feature—from the torque-rich engine to the locking differential—serves a purpose in maintaining progress against the terrain. The result is a cohesive system in which power, grip, stability, and durability converge to produce a dependable workhorse in environments where conventional vehicles would falter. In this sense, the essence of off-road trucks lies not in any single, flashy capability but in the integrated reliability that comes from engineering geared toward the realities of extreme terrain.

For a deeper dive into the material composition and the broader benefits these vehicles offer to industry and exploration alike, the detailed overview from a trusted industry source provides a comprehensive technical framework. It discusses how the integration of chassis design, powertrain resilience, and traction systems creates a robust platform capable of withstanding the demands of off-road work while maintaining safety and efficiency under varied operating conditions. This broader perspective helps contextualize the features described here within the larger story of off-road mobility, where performance is a function of deliberate engineering choices as much as field experience and operator skill. The end result is a clearer understanding of what off-road trucks are designed to do, why they are built that way, and how their hallmark features translate into real-world capability on the most challenging landscapes.

External reference for further technical insights: https://www.offroadtruckinsider.com/8×8-truck-material-composition-key-features-benefits

Rugged Reach: The Broad Spectrum of Off-Road Truck Applications Across Industry and Terrain

Off-road trucks are not merely larger versions of everyday pickup trucks. They are purpose-built machines whose strength lies in their ability to step off the paved path and into environments that would stall a standard vehicle. They operate where the ground is uncertain, where weather adds another layer of risk, and where the job requires both endurance and precision. Across markets, these trucks perform essential tasks, shaping how industries reach remote sites, manage risk, and move materials with surprising efficiency. Their value comes not simply from raw power but from a carefully balanced blend of traction, stability, durability, and the capacity to absorb punishment that would bend a lesser machine. When a site is unsettled by mud, sand, rock, or water, off-road trucks become the reliable workhorses that keep operations moving. They unlock possibilities in places others could only survey from a distance, and that perspective matters as much as any single lift or mile of travel.

The core of what makes off-road trucks so capable lies in design principles that target the harsh realities of non-paved environments. They sit higher than standard trucks, offering substantial ground clearance to clear rocks, ruts, and unexpected ditches. Their tires are not just large; they are engineered with aggressive tread patterns and rugged sidewalls that resist punctures and enhance grip on slippery surfaces. The suspension systems are reinforced to endure repeated impacts and to preserve payload integrity and crew comfort across irregular terrain. A robust chassis anchors the vehicle, while a drivetrain tuned for torque delivery at low speeds ensures traction on steep grades or through soft substrates. These characteristics come together to deliver predictable performance when a job’s success depends on moving heavy loads, navigating primitive access routes, and doing so with confidence rather than calculation born from fear of getting stuck.

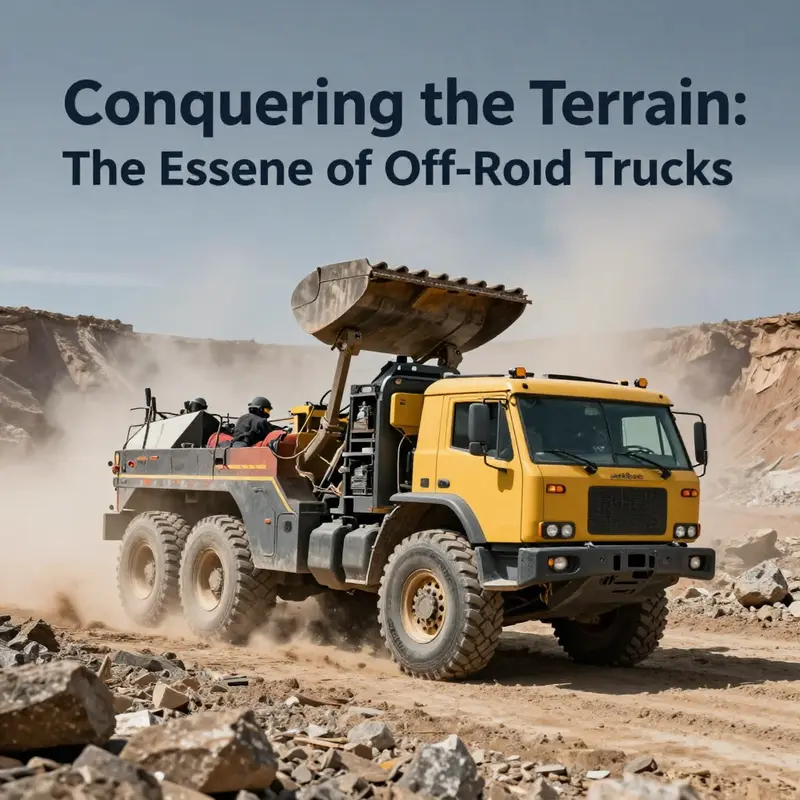

In industrial and mining settings, off-road trucks perform some of the most physically demanding tasks imaginable. Open-pit mines and remote quarries often sit far from paved roads, demanding a work philosophy that treats terrain as part of the job site. Here, the truck’s role is to ferry ore, rock, and construction materials between face and stockpile, sometimes over long, winding hauls that test brake cooling and drivetrain reliability. The machines must behave calmly under heavy payloads while cresting grades and braking on slippery benches. Their operation reduces the need for multiple travel modes and, crucially, lowers the risk of congestion on fragile, unpaved surfaces where precision matters. The efficiency gained by moving large volumes quickly translates into lower unit costs and faster project cycles, which, in turn, influences the overall economics of mining and processing operations.

Forestry and logging present a different kind of off-road challenge. Timber extraction often occurs in steep, uneven terrain where roads are scarce or nonexistent. Off-road trucks in this setting are tasked with transporting felled timber from remote stands to landing zones or to processing yards. They must manage the weight and uneven distribution of long, heavy loads while maintaining control on grades and through muddy switchbacks. In many forestry operations, the trucks are expected to minimize environmental impact as they traverse sensitive ecosystems. This means not only choosing routes that reduce soil compaction and root disruption but also employing equipment that integrates well with planning initiatives designed to protect waterways and wildlife habitats. The ability to move in tight spaces with limited turning radii and to respond quickly to changing ground conditions makes off-road trucks indispensable in the forestry value chain, where timing and reliability directly affect harvest yields and operational efficiency.

Agriculture, especially on large farms and agribusinesses, relies on off-road trucks when fields stretch beyond road-accessible boundaries. Harvest seasons can require moving crops, bales, seed, and machinery across uneven fields and rough access lanes. The versatility of these trucks allows farmers to adapt quickly to seasonal shifts, weather events, or emergent logistics needs within a single growing cycle. In some regions, the terrain itself becomes a constraint—flooded fields, dried crusts, or soft soil demands a vehicle that can distribute weight, avoid saturating the ground, and still deliver equipment and produce where needed. In each case, the trucks function as a bridge between agricultural productivity and the physical realities of the land. The result is a farming system that can scale its logistics with the seasons, keeping farms resilient even when access points are imperfect.

The construction sector frequently relies on off-road trucks to knit together remote work sites with supply lines that must withstand rough terrain and variable weather. On roadways that vanish into mountains or deserts, these trucks carry essential supplies, heavy building materials, and prefabricated components to locations where other vehicles would stall. They also support civil infrastructure projects that cut across challenging geographies, such as road alignments through hilly terrain or bridge approaches in remote valleys. The ability to move efficiently from one site to another reduces downtime, improves safety by removing the need for hazardous manual handling, and supports project schedules that would otherwise slip due to site inaccessibility. In this environment, the trucks are not just transport devices; they are the tactical backbone of construction logistics, offering dependable access when every hour counts and every mile of travel matters for budgeting and risk management.

In military and defense contexts, off-road trucks embody a different set of imperatives. They must deliver troops, supplies, and equipment across hostile or inaccessible terrains where brush, mud, sand, and snow threaten mobility. The design emphasis here centers on reliability, survivability, and the ability to perform under harsh environmental conditions. Features such as high ground clearance, all-wheel drive with locking differentials, and robust braking and cooling systems enable these vehicles to maintain momentum in conditions where civilian travel would pause. While the specifics of mission profiles are classified in many cases, the underlying truth is clear: when logistics reach the edge of the map, off-road trucks extend reach, reduce vulnerability, and enable rapid response. The same fundamental traits that empower disaster relief teams—durability, adaptive traction, and the capacity to haul heavy payloads over unforgiving ground—also inform the broader military utility of these platforms in peacetime and conflict alike.

Emergency response and disaster relief form a powerful counterpoint to the routine industrial applications. In floods, earthquakes, wildfires, or after severe storms, access roads can vanish overnight. Off-road trucks, with their broad capability to cut through mud, snow, water, and uneven terrain, become critical in delivering essential supplies, evacuating vulnerable populations, and supporting search-and-rescue operations. They can clear pathways, carry temporary shelter, and bring in field engineers to secure damaged infrastructure. In these moments, the value of an off-road truck is measured not only in its payload and speed but in its ability to operate consistently when conditions deteriorate. The same resilience that makes them effective in mining or construction translates directly into lifesaving roles when communities need decisive, practical aid rather than complex solutions.

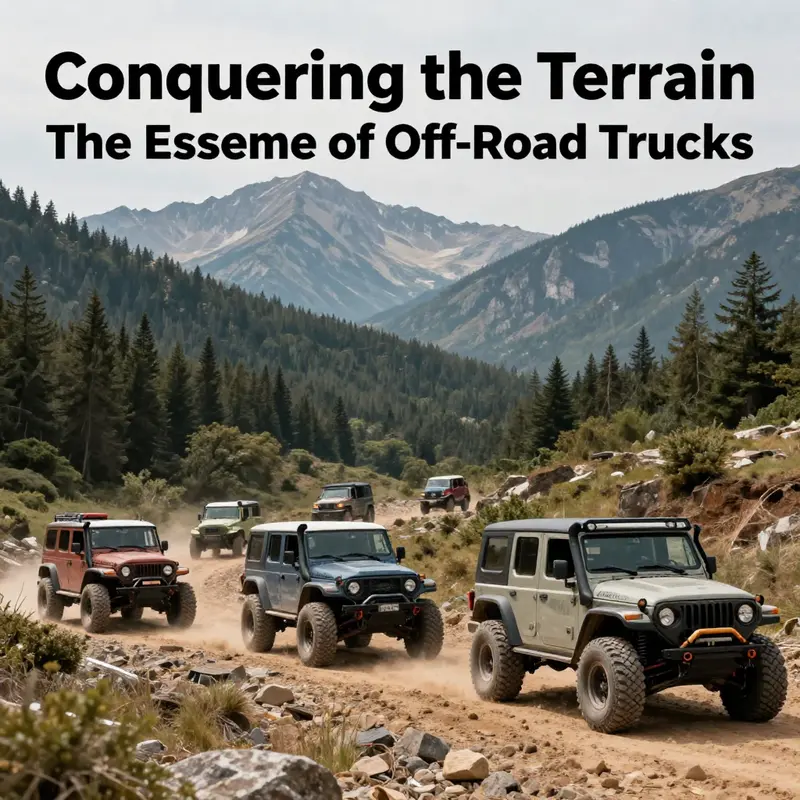

Beyond pure practicality lie the recreational and competitive dimensions of off-road trucks. Enthusiasts and adventurers push these machines to extremes, testing traction, endurance, and control in environments many machines would find insurmountable. Off-road racing, overlanding, and extreme-sport expeditions reveal a culture of capability and curiosity. While these activities are distinct from industrial operations, they share the same core belief in versatility and the willingness to confront terrain that challenges conventional vehicles. The growth of simulated experiences and remote-tracking simulations mirrors real-world testing, signaling how modern off-road trucks are increasingly integrated with data-driven feedback. In this sense, the line between work and play blurs into a shared pursuit of mastery over difficult ground, where technology and hands-on problem solving coevolve to push the limits of what is possible on surfaces that resist predictability.

Technology has become a unifying thread across all these applications. The latest generations of off-road trucks integrate smarter traction control, reinforced cooling for demanding duty cycles, and telemetry that monitors location, load, engine health, and environmental conditions. Machine learning and sensor fusion are being explored to predict soil sinkage and adjust wheel torque to preserve traction, stabilizing what would otherwise be a hazardous slide or stall. Autonomy, once a distant concept, is edging into the field as well, gradually increasing the amount of routine driving that can be performed by a vehicle while human operators monitor and intervene as needed. These developments do not remove the operator from the equation; they augment capability and safety, enabling teams to plan more precise routes, optimize fuel use, and respond more quickly to changing work site conditions. The result is a more robust, efficient, and resilient set of operations that can adapt to weather, ground truth, and the evolving demands of a project.

In the broader trajectory of off-road trucks, several overarching themes stand out. First, the demand for movement in challenging environments continues to grow as industries expand into previously inaccessible areas. Second, the convergence of heavy-duty engineering with digital tools enables more precise planning, safer operation, and longer component life under stress. Third, the push toward electrification and hybridization promises to reshape the environmental footprint of off-road work, potentially reducing emissions and cooling demands while expanding the range of mission profiles that can be tackled by a single fleet. Finally, the social and operational value of these vehicles emerges most clearly in their capacity to keep critical activities running in places where the road ends and the terrain begins. In that sense, off-road trucks are not merely vehicles; they are enablers of possibility at the margins where the most important work often occurs.

The evolving landscape of off-road trucking thus invites consideration of how best to deploy these machines across sectors. For a sense of the broader shift toward electrified, smarter platforms, the idea of a revolution in electric construction equipment offers a useful frame. The conversation around this transition centers on reliability, lifecycle costs, and the way new powertrains alter maintenance needs and yard logistics. As the industry experiments with modular designs, swappable components, and remote diagnostics, fleets can tailor their assets to the peculiarities of each site—from deep forest to arid desert, from floodplain to rocky hillside. The promise is not merely faster transport but safer, cleaner, and more sustainable operations that can be scaled to meet demand without abandoning the rugged resilience these trucks provide.

In practical terms, the applications of off-road trucks are about continuity. They keep projects advancing when conventional vehicles fail to perform. They enable responses that protect people and property in emergencies. They extend economic activity into remote locales, supporting livelihoods in mining towns, forest communities, and agricultural belts that depend on dependable logistics. They support defense and humanitarian missions that require robust, mobile platforms capable of operating where terrain behaves like a barrier. They also offer a pathway for recreational exploration that pushes the boundaries of what is possible with heavy-duty, off-road machinery. This is not a single-use technology; it is a versatile class of machines whose value lies in adaptability, reliability, and the capacity to transform rough terrain into usable space. In short, off-road trucks expand the map of where industries can work, and they do so with a blend of force, finesse, and practical engineering that remains compelling across time and context.

For readers exploring the future of these machines, a broader context about how electrification and advanced construction equipment are converging can be insightful. See the discussion on the electric construction equipment revolution for a sense of how powertrains and energy management strategies are evolving in tandem with the needs of harsh field conditions. electric construction equipment revolution

External resource: For a general overview of off-road vehicle categories and their operating environments, see https://en.wikipedia.org/wiki/Off-road_vehicle.

Rugged Roads, Clear Roles: Understanding Off-Road Trucks Versus Regular Vehicles

What it means when a truck is labeled as off-road goes beyond the simplest sense of capable tires or a raised body. It speaks to a design philosophy tuned for places where pavement ends and real testing begins. The term often invites a mental image of a bulky vehicle wrestling through mud, rock, sand, or snow, a machine that can endure conditions a standard sedan would treat as a warning sign. Yet the phrase also asks for a more precise understanding: off-road trucks are not merely larger versions of everyday pickups or SUVs; they are purpose-built tools for climates and terrains where regular road vehicles would falter, stall, or break. The distinction matters, because it frames how these machines are engineered, how they perform, and how they fit into tasks as varied as mining logistics, forest operations, remote exploration, and emergency response. This chapter unfolds that distinction with careful attention to design, performance, and purpose, weaving a narrative that respects the seriousness of off-road work while recognizing how it reshapes our expectations of what a vehicle can do when the world stops being a smooth stretch of asphalt.

From the outset, the core difference centers on purpose. Regular vehicles are optimized for paved roads and everyday routines. They prize fuel efficiency, comfort, quiet operation, and predictable handling. They ride on lighter frames with suspensions calibrated to minimize harshness and maximize highway poise. Passenger-oriented tires keep noise and wear low, even as weather and road surfaces vary. The interior aims at practicality and comfort for daily commutes, with features that support long hours behind a steering wheel but not continuous encounters with obstacles, shoulder-deep ruts, or water crossings. In contrast, off-road trucks are designed to ensure progress in the face of real resistance. The tires are often oversized and deeply treaded for traction in mud, sand, rock, and snow. The ground clearance is not a luxury feature but a survival tactic, allowing a vehicle to clear rocks, logs, and uneven terrain without scraping its underbelly. The chassis and suspension are reinforced, not to curr y the soft edges of a highway ride but to absorb repeated pounding from rough trails, washouts, and cross-courses where the surface itself is the obstacle.

That difference translates into concrete engineering choices. An off-road truck typically features a robust, reinforced chassis that resists twisting and bending under load, a critical attribute when the drivetrain must transfer torque through unpredictable ground. The suspension is built for travel rather than cosseting riders, with greater articulation to keep wheels in contact with the ground as the chassis tilts and rocks on steeper grades. Tires are not just larger; they are functionally specialized, with tread patterns designed to bite into loose surfaces and channel away mud or sand so the rubber can bite rather than slide. Traction control systems sit alongside advanced driveline configurations, including locking differentials, to ensure that grip is available on both axles when one wheel might otherwise spin freely. Every component—brakes, cooling systems, even the transmission—meets a higher bar for endurance, because the scenarios these machines confront rarely offer a quick rescue or a short tow back to civilization.

The comparison with regular vehicles becomes especially meaningful when we consider load demands and the nature of journeys. Off-road trucks in mining or construction sites are not about cruising between coffee shops; they shuttle gear, ore, or materials across uneven, often treacherous terrain. The loads are heavy, the routes long, and the environment harsh. In remote exploration or wildlife research, a truck serves as a mobile base, staying productive through long intervals between maintenance, with systems designed to endure heat, dust, humidity, and cold. In military or emergency-response contexts, the emphasis shifts further toward reliability, rapid repairability, and sustained performance under stress. These roles demand the ability to press on regardless of weather, terrain, or adversarial conditions. Regular vehicles, however capable in their own right on average roads, are not intended for sustained off-road duty. They accumulate damage when exposed to continuous vibration, mud, water ingestion into the engine bay, or repeated impacts that would pass unnoticed on signalized city streets.

Design and construction reveal this divergence in even more explicit terms. The reinforced chassis of an off-road truck is engineered to resist the cumulative fatigue that comes from negotiating rock gardens and deep ruts. Heavy-duty suspensions provide substantial wheel travel and robust damping, enabling the vehicle to maintain traction while the body leans and shifts over obstacles. The tire choice—be it aggressive all-terrain or mud-terrain rubber—prioritizes grip over fuel economy, and the tread compounds are selected to resist chunking or tearing when faced with sharp rocks or abrasive surface layers. A key feature often overlooked by casual observers is the ability to modulate traction through advanced systems, including locking differentials that can force both wheels on an axle to rotate at the same speed. In a slippery wash, this can prevent the vehicle from losing grip if one wheel is perched on a rock and the other on slick mud. Such a setup is not primarily about speed; it is about controlled, deliberate progress in environments where smoothness would be an obstacle.

The communication between design choices and operating environments is especially clear when contemplating powertrains. Off-road trucks tend to emphasize torque over raw horsepower, because lower-end torque directly translates into the ability to inch through rutted trails, haul heavy payloads up steep grades, or push through soft sand without burying the frame. The driveline may rely on a drivetrain architecture that can withstand the kind of stress typical of rough terrain—systems that tolerate sustained high loads and occasional impact without overheating or component failure. The cooling system is likewise built with resilience in mind, engineered to keep transmissions and differentials within safe temperature ranges even when airflow is compromised by a rock outcrop or a dusty canyon. The result is a vehicle that remains functional when the environment itself is a barrier. In a regular vehicle, the emphasis remains on smooth, quiet, efficient operation under predictable conditions. The engine, transmission, and suspension harmonize to deliver comfortable daily travel, not to negotiate cliffs or riverbeds.

The historical thread behind off-road designs also helps illuminate what makes a truck different in the most demanding situations. A note about engineering lineage points to a philosophy of redundancy and durability that has long informed the development of extreme-duty trucks. Some historic driveline concepts introduced decades ago—such as backbone frame designs or independent, multi-wheel suspensions—were conceived to distribute stress more evenly and maintain wheel contact on uneven surfaces. Independent suspension on every wheel, a feature favored in certain rugged designs, exemplifies the mindset: it preserves wheel-to-ground contact even as the chassis tilts, a crucial advantage when traversing rugged terrain where a single point of contact can determine the path forward. Such concepts, refined over years, reveal a persistent goal: create machines that can function in environments where a standard road-going vehicle would simply fail to proceed. The lesson here is not nostalgia for old mechanics but a sober recognition that resilience in the field hinges on how the machine behaves when the surface beneath it refuses to cooperate.

The practical implications for users are just as important as the engineering. Off-road trucks are used in contexts where reliability is non-negotiable. Miners rely on trucks that can operate around the clock, in dust and heat, across uneven roads and undeveloped paths. Forestry operations require equipment that can carry heavy loads and detour around fallen timber or boggy ground. In remote area exploration, the vehicle is not a mere means of transport but a mobile workshop and a shelter, with systems designed to be serviced in the field rather than hauled back to a shop. In military and emergency missions, the demand is for robustness, ease of field maintenance, and the ability to perform in far-flung geographies that stretch the resources of teams and spare parts to the limit. These use cases illuminate why off-road trucks are not overbuilt luxuries but essential tools for specific tasks where the terrain itself sets the terms for movement.

This chapter also invites a broader reflection on how audiences perceive off-road capabilities. It is easy to conflate off-road performance with the sense of adventure that accompanies overlanding or the spectacle of off-road racing. Yet the core value lies in reliability and capability under stress. The vehicle’s interior, while rugged, may still be designed for practical field use, with layouts that prioritize cargo space, ease of cleaning, and modularity for different mission payloads. Comfort and creature features remain secondary to the practical demands of mission timeframes—think of an interior that can be cleaned quickly after a muddy stint, or seating arranged to accommodate gear and crew rather than a single driver’s comfort for a five-hour commute. In short, the off-road truck embodies a balance: all-terrain capability and heavy-duty durability coexisting with a sense of purpose built into its core architecture.

As readers consider what this means for the broader article on understanding off-road trucks, a practical takeaway emerges. Off-road trucks are not just about being able to leave paved surfaces behind; they are about sustaining progress where each mile tests a different facet of the vehicle’s design. Their performance is not best judged by top speed or highway acceleration but by the consistency of traction, the effectiveness of cooling under load, the ease of field maintenance, and the ability to carry and protect essential equipment through demanding terrain. The line between off-road trucks and regular vehicles is not a fuzzy boundary but a spectrum defined by intent, engineering, and application. A vehicle in the regular-vehicle category lives in a high-certainty environment: the road is known, the conditions are controlled, and the mission is predictable. An off-road truck lives in a high-uncertainty environment: the ground is unpredictable, obstacles are commonplace, and the objective is to advance despite, or even because of, those constraints. To truly grasp what it means by off-road trucks, one must listen to the terrain as much as to the engine, and let the design choices speak for the demands they were built to meet. If the reader seeks a deeper, more technical dive into the mechanics that enable such performance, consider exploring the practical expertise behind diesel systems and maintenance, such as this guide: Mastering Diesel Mechanics: Your Step-by-Step Path to Success. This link offers a gateway to the kinds of hands-on insights that power the field, reinforcing the idea that knowledge of the underlying systems is essential to truly understanding off-road capability.

In closing, the distinction between off-road trucks and regular vehicles rests on more than the sum of their parts. It is a difference of intention, environment, and expectation. Off-road trucks are built to conquer the unknown, to endure the unexpected, and to deliver performance when the road simply stops. Regular vehicles, conversely, are optimized for predictable travel on predictable surfaces. Together, they illustrate a broad spectrum of mobility: one designed for the extremes, the other tailored for the routine. Appreciating this spectrum helps readers interpret the broader world of trucks and vehicles, and it grounds the discussion in a clear, practical understanding of why off-road trucks matter in contexts ranging from mining to emergency response to remote exploration. For readers who seek more context about the terrain-focused engineering that underpins these vehicles, the following external overview provides additional technical depth: https://www.madisonhilloffroad.com/.

Final thoughts

In summary, off-road trucks are not just vehicles; they are gateways to adventure, exploration, and essential tools for various industries. Their distinctive features, tailored to conquer challenging terrains, make them irreplaceable assets for enthusiasts and professionals alike. Whether it’s for racing through rugged courses, performing agricultural duties, or facilitating heavy-duty tasks at construction sites, these trucks embody a commitment to durability, performance, and functionality that standard vehicles simply cannot replicate. Understanding what makes off-road trucks special empowers us to fully appreciate their role in the adventure of life, waiting to be tackled one rugged journey at a time.