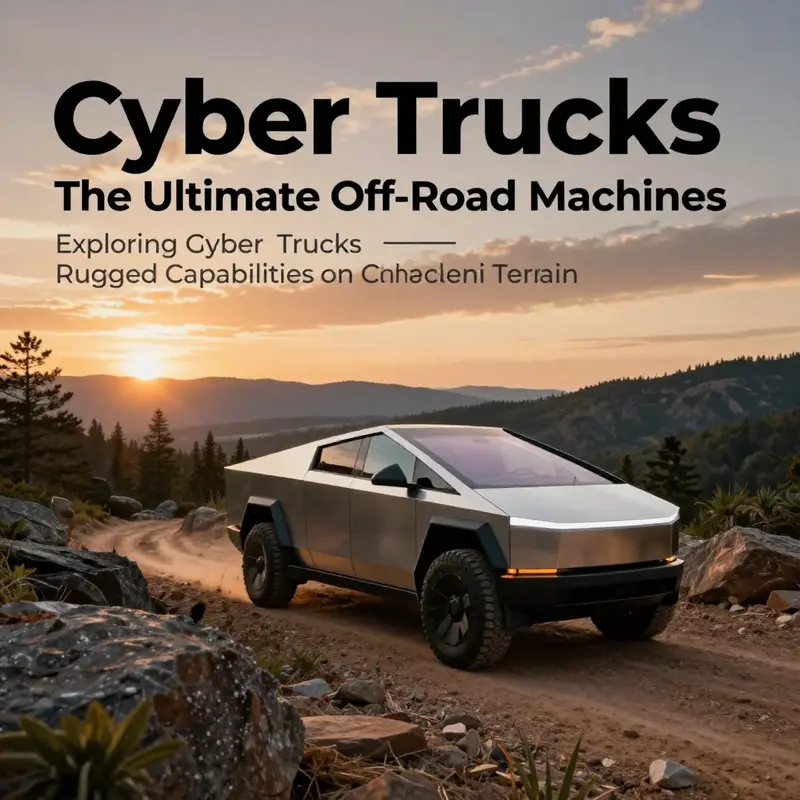

In the realm of off-roading, where adventure meets the unpredictable wilderness, the Cybertruck emerges as a groundbreaking contender. Its advanced engineering and innovative features challenge long-standing notions of what an all-terrain vehicle can achieve. Throughout the following chapters, we will delve into the specifics of the Cybertruck’s design that facilitate superior off-road performance, compare its capabilities against traditional vehicles, and hear from real users who have put it to the test in rugged environments. Whether you’re an off-road enthusiast, a participant in adrenaline-pumping races, or a landowner needing reliability, the rugged promise of the Cybertruck stands at the forefront of modern automotive adventures.

Why the Cybertruck Excels Off-Road: Systems, Strength, and Real-World Ready Design

Why the Cybertruck Excels Off-Road: Systems, Strength, and Real-World Ready Design

The Cybertruck changes how we think about an electric pickup in the wild. It is not a softened urban vehicle with an off-road badge. Instead, its engineering centers on rugged terrain performance. That begins with a fundamentally different architecture: a high-torque electric powertrain, a tough exoskeleton, and adaptive systems that can be tuned for conditions. Together, these features let the vehicle tackle mud, rocks, sand, and water with confidence and control.

At the core of its capability is the suite of off-road systems that work in concert. When the driver selects Off-Road Mode, the vehicle does more than raise itself. The suspension lifts to significantly increased ground clearance, damping adjusts to soak impacts, and traction systems adopt settings designed for low-grip surfaces. The software coordinates motor output, braking, and steering inputs to maintain momentum without sacrificing control. This means climbs feel more linear and predictable than with many combustion pickups, because electric motors supply instantaneous torque across a broad band.

A standout feature is the vehicle’s ability to alter the amount of permitted tire slip. On loose sand or gravel, allowing slight slip at the wheels can prevent digging in and losing momentum. Whereas conventional traction control clamps down aggressively and can bog the vehicle, the Cybertruck’s systems tune intervention so it can maintain speed across shifting surfaces. For drivers who spend long hours on trails, this reduces fatigue and improves progression over otherwise stop-start terrain.

The adjustable ride height is more than a convenience. At its highest setting, it clears deep ruts, ledges, and large obstacles that often define true off-road trails. The range of settings lets a driver dial the clearance and damping to favor comfort, control, or maximum obstacle negotiation. Above that, dedicated terrain profiles—Smooth, Rugged, and Clearance—preset suspension and drivetrain responses so the vehicle behaves predictably when conditions change rapidly. These presets also simplify operation for less experienced off-roaders who want competent performance without deep technical setup.

Specialized modes extend capability into specific hazards. Wade Mode raises the chassis and activates protective measures for the battery pack and high-voltage systems. Instead of relying on passive sealing alone, the vehicle actively manages pressures to discourage water ingress during shallow water crossings. Trail Assist helps maintain a constant, steady pace over uneven ground, taking much of the micro-management out of long trail drives. That steadiness matters on technical lines where a sudden surge or dip can unsettle the vehicle and cost progress.

Traction hardware complements the software. Locking differentials, when engaged, distribute torque evenly to wheels, so a stuck wheel can be bypassed by drawing power to the others. For climbs and sideways-on rock faces, predictable torque distribution is the difference between clearing an obstacle and getting stranded. Paired with selectable handling balance settings, drivers can bias the vehicle toward stability or agility depending on the route. The interface lets a user favor a steadier, front-weighted feel or a more agile, rear-driven response—choices that suit towing, solo overland runs, or tight trail maneuvering.

Durability matters as much as control. The vehicle’s outer shell uses a high-strength metallic exoskeleton combined with composite elements where weight savings help efficiency and balance. The result is superior resistance to dings, deformation, and corrosion. In remote use, that robustness reduces the chance of body damage from brush, rocks, or trail hazards. Underbody protection, reinforced mounting points, and serviceability are all considered in the design, making repairs simpler after hard use.

Real-world off-road performance also depends on contact patches: the tires and wheels. While the factory equipment provides an excellent balance for mixed use, many owners pursuing serious off-road work upgrade to purpose-built wheels and tires. Forged aluminum wheels with high load ratings resist impact damage that crush-cast wheels suffer from. Tire choice—aggressive all-terrain or mud-terrain tread—dramatically alters capability, flotation, and self-cleaning. Those upgrades, when paired with the vehicle’s suspension and torque characteristics, lift its practical limits.

Power delivery is another advantage. Electric drive gives instant torque, which is invaluable when crawling over obstacles or pulling through sand. The lack of gear shifts means smooth delivery and no interruption of torque under load. For steep, technical climbs, the motors can be modulated precisely to keep traction without the jerking feel of some low-speed transmission behavior in combustion trucks. That precision also reduces the chance of spinning a wheel enough to fling sand or lose grip.

Yet with all these strengths come operational caveats. Off-Road Mode changes handling and should be used only in appropriate environments. The vehicle’s altered behavior can be unsafe or even illegal on public roads when configured for extreme clearance or reduced stability aids. Battery and motor cooling are engineered for off-road loads, but sustained high-load conditions—like long, steep, hot climbs—require attention. Drivers should monitor thermal indicators and plan routes that allow for recovery or cooling breaks if needed.

Maintenance and preparation remain central to successful off-road use. Regular inspection of wheel bearings, suspension mounts, steering linkages, and underbody panels prevents minor problems from becoming trip-ending failures. Seal inspections after water crossings are vital, even with wade protections engaged. Simple items like a basic recovery kit, traction aids, and a spare wheel and tire suitable for the chosen terrain pay dividends when help is distant.

The platform also lends itself to aftermarket refinement. Reinforced wheels, heavy-duty skid plates, and tuned shock packages extend capability without sacrificing the core benefits of the electric architecture. Many upgrades focus on resilience and repairability: replaceable rim edges, sacrificial wear surfaces, and modular bumpers that accept recovery points and winches. When upgrades remain mindful of weight and aerodynamics, they keep range and handling predictable—important for long overland trips.

Safety and legal considerations should guide adventurous tuning. Locking differentials, stability reductions, and aggressive tire choices all change handling in ways that demand respect. Drivers must understand how setup affects braking distances, turn-in behavior, and lane-change responses on mixed surfaces. For organized events or remote expeditions, informing support teams about vehicle configuration reduces rescue complexity.

The synergy between hardware and software is what ultimately separates a good off-road electric pickup from a merely capable one. Adaptive systems that learn and respond to the driver’s inputs turn momentary decisions into sustained performance. A vehicle that can change its stance, pressurize sensitive systems, and manage torque precisely reduces the cognitive load on the driver. That lets more attention stay on reading terrain and planning lines.

For anyone weighing whether this electric pickup is good off-road, the answer lies in the integration: a durable shell, a responsive high-torque drivetrain, adjustable clearance, and terrain-aware software. Together, these elements form a coherent package ready for serious trails, provided the driver respects the limits and prepares accordingly. Owners who combine appropriate tires, reinforced wheels, and smart aftermarket protections will find the vehicle moves into a higher class of capability.

For a deeper dive into how the off-road modes and settings operate, the manufacturer’s off-road driving guide offers technical details and operational notes that relate directly to these systems. For additional context on electric heavy equipment and rugged vehicle adoption trends, see the article on the electric construction equipment revolution: https://dirtantrucks.com/volvo-electric-construction-equipment-revolution/.

Further technical specifics and official operational guidance are available from the vehicle’s off-road driving documentation: https://www.tesla.com/support/cybertruck-off-road-driving.

How Cyber-Style Electric Pickups’ Technical Kit Turns Rough Trails into Manageable Terrain

Engineering the Ride: how an electric pickup’s systems combine to conquer off-road challenges

The difference between a capable off-roader and a mere road-capable truck lies in how its systems work together. For cyber-style electric pickups, off-road performance is not a single spec on a sheet. It is the orchestration of suspension, traction control, power delivery, body durability, and software logic. Each element addresses a specific threat posed by rocks, ruts, mud, water, and steep approaches. When these elements are designed to communicate, the whole becomes greater than the sum of its parts.

At the core is an adaptive suspension system that changes ride height and damping in real time. When the driver selects an off-road preset, the suspension raises the chassis to increase ground clearance. It also stiffens or softens damping to control body motion over uneven surfaces. That combination reduces the chance of underbody contact while keeping wheels planted. On fast desert sections, the system favors compliance to soak up repetitive bumps. On technical rock fields, it prioritizes articulation and slower, controlled movement. The noticeable benefit is not just clearance, but the vehicle’s ability to keep tire contact with changing terrain.

Complementing suspension is a suite of terrain selection modes. Instead of attempting one-size-fits-all settings, these modes tailor the vehicle’s behavior. A “rugged” mode balances damping and traction for mixed trails. A “clearance” mode raises ride height to its maximum and modifies throttle response to prioritize slow, deliberate movement over acceleration. A dedicated wading mode adds another layer of protection. This mode raises suspension further and enacts safeguards for vulnerable components. It pressurizes critical housings and adjusts thermal and electrical systems to reduce water ingress risk. Together, these presets let the driver quickly match the vehicle to the trail.

Traction management has evolved from simple differential locks into deeply integrated electronic systems. Locking differentials remain important, but modern control logic can engage torque vectoring, modulate brake inputs, and command individual wheel torque. That allows the vehicle to route power away from spinning tires toward those with grip. The result is consistent forward progress in situations where a conventional driveline would hunt for traction. When combined with instant electric torque, the vehicle delivers controlled bursts of power without the lag or clutch chatter of older designs.

Electronic stability control plays a crucial role off-road. Instead of an on/off safety net, this system offers graded intervention. A standard mode applies maximum correction to keep the vehicle upright and predictable. A reduced-intervention mode lets experienced drivers allow controlled slides or manage momentum in loose surfaces. This flexibility matters on gravel descents or sand washes where a bit of slip can aid direction control. But reduced intervention demands caution. When stability aids are dialed back, the driver becomes the primary stability manager, and errors have more immediate consequences.

The handling balance slider is a deceptively powerful feature. By shifting the dynamic bias toward a more stable front-drive feel or a more agile rear-drive responsiveness, drivers can tune the vehicle’s on-trail personality. In tight, technical sections, a more stable setup reduces twitch and helps maintain a chosen line. On broad, undulating trails, a more rear-biased feel can unlock better steering rotation and a sportier response. This level of personalization helps drivers match vehicle behavior to terrain and skill.

Durability and corrosion resistance are often overlooked, yet they define long-term off-road value. A hybrid body structure that combines high-strength steel with composite elements reduces denting and resists the fatigue that kills conventional panels. Corrosion resistance extends service life in salty or wet environments common to coastal trails and winter excursions. Modular body elements and removable panels make repairs easier after hard use. For example, aftermarket wheels designed for extreme use often include sacrificial rim sections that protect the main structure. Those wheels can handle heavy loads and impacts while simplifying field repairs.

Battery and electrical protection are unique considerations for electric pickups. Unlike liquid-cooled powertrains, high-voltage battery packs require special attention when facing water or deep mud. Dedicated wading modes adjust sealing strategies and internal pressurization to keep water out of vulnerable areas. Thermal management is altered during extended low-speed crawling to avoid overheating while regenerative systems are tuned down to prevent sudden torque spikes. Drivers should be mindful that extreme off-road use affects thermal and charge states, so planning for charging and cooling becomes part of trip preparation.

Regenerative braking adds another layer to traction management. On loose or slippery surfaces, aggressive regeneration can upset wheel traction. The ability to lower regen settings during off-road segments preserves wheel slip characteristics and prevents abrupt retarding. Drivers can then rely on mechanical braking and engine-replacement strategies in the electric system to modulate speed without sacrificing control.

Powertrain layout determines how torque is delivered. Multi-motor setups offer redundancy and immediate torque across each wheel. This instant response is an advantage on steep climbs and in soft sand, where a quick torque pulse can break suction or move the vehicle forward without the delay typical of combustion engines. Additionally, multiple motors allow more precise torque distribution for cornering and traction. The downside is weight and complexity, which engineers mitigate through packaging and smart software control.

Real-world trail use highlights how these systems interact. Approaching a water crossing, the vehicle can raise its ride height, enable wading protections, and reduce regeneration. Midway through a rocky sector, locking differentials engage as the suspension lowers slightly for stability. On a sandy climb, instant torque prevents bogging while traction control prevents excessive wheel spin. The driver experiences a single, predictable machine rather than separate, disjointed features.

Maintenance and aftermarket considerations matter too. Robust off-road use puts stress on suspension mounting points, wheel bearings, and protective seals. Regular inspection of seals, underbody protection, and wheel components preserves capability. Several aftermarket options focus on improving impact resistance and repairability. Heavy-duty forged wheels with replaceable rim sections and reinforced hubs extend service life. Reinforced skid plates and modular bumper systems protect critical nodes and simplify field repair.

Safety and legal use must guide how off-road modes are applied. Off-road presets change handling and response. They are not intended for public roads, where altered dynamics can be unsafe or illegal. Responsible drivers engage these features only in appropriate environments and understand how reduced electronic intervention affects vehicle behavior. Training, practice, and a conservative approach to unfamiliar trails reduce the chance of mishaps.

Finally, the evolution of heavy electric equipment offers lessons for off-road electric vehicles. Innovations in sealing, thermal management, and modular build seen in larger electric machines inform pickup design. For a look at how electric heavy equipment is evolving, see this discussion of electric construction equipment advances (https://dirtantrucks.com/volvo-electric-construction-equipment-revolution/).

Collectively, these technical features explain why cyber-style electric pickups can excel off-road. They combine adaptive chassis control, precise torque management, component durability, and software intelligence. When used thoughtfully, this package provides strong capability across varied terrain while offering tunability for driver skill and trail demands. For authoritative details on specific off-road modes and demonstrations, refer to the official driving documentation: https://www.tesla.com/cybertruck/driving

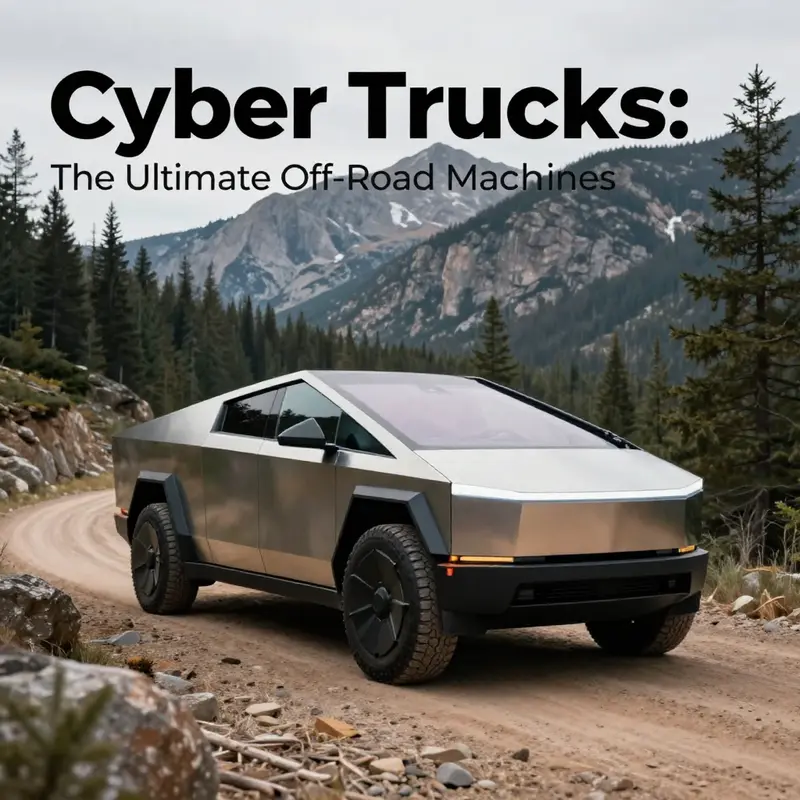

Rugged Redefinition: The Modern Electric Utility Truck Against Traditional Off-Road Giants

Off-road capability has long been measured by how a vehicle handles rough, slow-speed terrain, deep ruts, and water crossings. The arrival of a modern electric utility truck changes that conversation in two ways: the drivetrain and chassis engineering, and the way software and adaptive systems give the driver clearer feedback. This is not just a different flavor of off-roading; it is a shift in what capability means when the ground does not cooperate. The electric platform offers instant torque, precise traction management, and high clarity feedback that can feel unfamiliar to drivers raised on diesel power. Yet it is coupled with a design philosophy built for real world endurance and rugged reliability that matter on long or remote trips. The discussion of good off road becomes more nuanced when we add Wade Mode, Trail Assist, locking differentials, and adjustable ride height to the mix. These systems turn rough terrain into a more controllable, predictable challenge rather than a test of brute force.

The powertrain’s instant torque helps with confident climbs, careful throttle control on mud, and maintaining momentum on uneven surfaces. Rapid charging and battery management support longer trips away from civilization, so you can stay on the trail rather than hunting a fuel pump. The body structure uses a stainless exoskeleton and selective carbon fiber to resist rock strikes and corrosion, while the chassis communicates mass and balance back to the driver for intuitive control. Inside, a practical cabin with a roomy cargo bed and a gesture-based interface keeps focus on the trail and on safety through driver assistance and real-time data.

Market realities and regulatory landscapes shape how widely this capability is available. Some regions welcome rapid deployment while others slow adoption due to regulatory or charging infrastructure gaps. The environmental case is favorable too: zero tailpipe emissions during operation and the potential for lower lifetime emissions when charged from clean energy. Compared with traditional ICE pickups, the electric option offers instant torque and advanced traction control but adds considerations about weight, braking, and the need for charging on longer expeditions. Taken together, these elements broaden the practical envelope of off-roading without diminishing the workhorse ethos.

In sum, the modern electric utility truck redefines off-road capability not as a binary choice but as a spectrum of optimized power, grip, and durability. It invites drivers to think of the trail as a dynamic environment rather than a static obstacle course and shows how software and hardware can work together to preserve momentum, protect the drivetrain, and reduce fatigue on long days on rough terrain.

How Cyber Trucks Live Up to Off-Road Claims: Real Use, Fieldwork, and Owner Stories

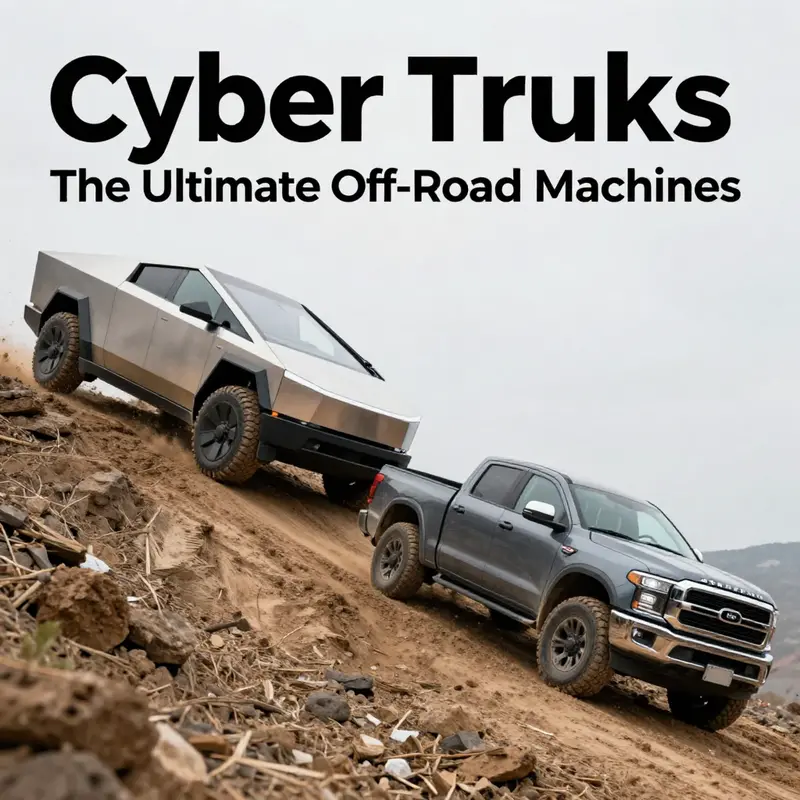

Real-world terrain, real-world answers. Owners and field testers report that these trucks are built not just to look like science fiction, but to handle the kinds of terrain that traditionally challenge light-duty pickups. The combination of adjustable ride height, multiple driving modes, and a high-torque electric drivetrain creates a package that behaves differently from internal-combustion trucks — often to clear advantage when the ground gets ugly.

Reports from trail runs and remote work sites consistently emphasize clearance and torque. The air suspension can lift the chassis to a Very High setting, offering up to about sixteen inches of ground clearance. That alone changes what obstacles are negotiable. Rocks and roots that force slow, deliberate line choices in conventional pickups become manageable with the extra inches and the ability to alter damping on the fly. Trail managers and weekend explorers mention taking lines they would otherwise avoid, because the truck’s geometry and wheel travel smooth the ride and reduce the chance of burying a low-slung skid plate or getting hung up on a ledge.

Equally important to raw clearance is torque delivery. Electric motors produce instant tractive effort. That instant thrust is a practical advantage on loose slopes, in mud, and when exiting soft sand. Drivers describe being able to modulate throttle in fine increments to maintain momentum without aggressive clutch or transmission inputs. On steep, rutted climbs this immediate response reduces the need for gear hunting and keeps momentum predictable, which lowers the risk of spinning wheels and losing forward progress.

A major theme in owner feedback is how the truck’s off-road modes change driving dynamics. Rugged mode softens and re-tunes damping to let the chassis roll and articulate over broken terrain. That helps keep tires planted and preserves traction across uneven surfaces. Clearance mode prioritizes height, pushing the suspension to extremes to get over big obstacles. Users who switch between these settings on long routes say it feels like carrying multiple specialized vehicles in one: comfortable and composed on forest service roads, but willing to stretch into technical sections without sacrificing safety.

Built-in traction aids are another staple of successful field testing. Locking differentials and finely tuned torque distribution systems stop wheelspin from turning into a stalled recovery. On mixed-surface trails where one wheel might be in the air and another in a rut, drivers report the vehicle quickly reroutes power to gripping wheels. This capability, combined with the absence of an internal-combustion drivetrain’s torque lag, makes the truck behave more predictably when the surface changes underfoot.

Beyond trail performance, the truck has found practical roles at work sites and in off-grid living. The cargo bed integrates 120V and 240V outlets, creating a mobile power hub for tools and campsite equipment. Contractors appreciate being able to run saws, compressors, and lights directly from the truck without hauling a separate generator. In extended power outages, some users have leveraged bidirectional power to supply a small home with essential circuits, keeping refrigeration and heating or medical equipment running. These features turn the vehicle into a versatile energy resource for remote job sites and emergency response situations.

This crossover between mobility and power puts the truck into a different conversation than traditional off-road rigs. Instead of being just a transporter, it becomes a compact utility platform. There’s growing interest from professional crews who need both access and on-site power. Evidence of this trend aligns with recent shifts toward electrified work machines and site equipment, positioning electric trucks as central to the modern jobsite toolkit. For context on how electrification is reshaping construction equipment roles and expectations, see the coverage on the electric construction equipment revolution: Volvo electric construction equipment revolution.

Durability gets a lot of commentary. The unique body material and architecture resist dents and corrosion differently than conventional sheet-metal trucks. Owners who test their trucks on rocky trails and through brush often point to fewer cosmetic consequences after hard use. The windshield and glass technologies also provide extra resistance to small impacts and flying debris, which is welcomed when gravel and branches are part of the daily routine.

Comfort and safety are integral to long excursions. A high-efficiency cabin filter and a sealed circulation system cut the dust and particulate load for occupants. This proves useful on dusty fire roads and during long desert crossings, where a clean cabin maintains concentration and reduces fatigue. Safety systems tailored for low-speed trail use, along with adaptive stability controls, help drivers maintain control in tricky situations. Experienced drivers caution, however, that dialing down electronic aids too far can remove valuable protections. Reducing stability intervention may allow expert drivers more freedom, but it raises the chance of losing control if traction disappears unexpectedly.

Performance-focused variants add another dimension for off-roaders who want speed with capability. Multi-motor setups deliver the kind of acceleration usually reserved for high-performance cars. On open, graded dirt roads, drivers report brisk, controllable acceleration that makes merging or overtaking easier. While this performance thrills, it also changes how a vehicle behaves on rough ground. Rapid acceleration can unsettle a lightly loaded chassis, so operators emphasize measured inputs when exploring at speed.

Field users also note a different approach to maintenance and recovery. Fewer moving parts in an electric drivetrain mean some traditional failure modes are less common. At the same time, service procedures for high-voltage systems, suspension electronics, and battery pack protection require trained technicians. When things go wrong off-road, recovery techniques resemble those used for heavy, complex vehicles. Owners recommend investing in modular recovery gear and portable charging or battery management tools when planning extended off-grid trips.

Real-world testing highlights a few trade-offs. Tire choice becomes even more critical, because heavy battery packs change load distribution and inertia compared to lighter conventional pickups. Sidewall protection and puncture-resistant constructions matter on rock gardens. Weight also affects towing and floatation in soft sand; lower-pressure techniques and wider footprints help, but they require planning. Drivers who prepare for the vehicle’s unique mass and energy profile avoid many potential pitfalls.

Community reporting shows that early skepticism often gives way to respect after hands-on experience. The combination of robust protection, adjustable suspension, and integrated power tools changes the baseline of what off-road vehicles can do. Those who depend on a vehicle for both access and work increasingly value the ability to arrive at a remote location and immediately deploy power and tools without additional equipment.

Finally, public demonstrations and documented trials remain useful resources for owners and prospective buyers who want to see limits and capabilities. Official footage and owner videos reveal the truck negotiating steep, broken terrain, crossing shallow water, and powering field equipment. These sources help translate specification into practical understanding, showing how features perform when conditions are truly challenging. For further technical specs and demonstration material from the manufacturer, see the official features page: https://www.tesla.com/cybertruck

Overall, the real-world record suggests these trucks are more than capable off-road. They require different preparation and respect compared to conventional rigs, but they offer a distinctive mix of clearance, torque, modular power, and rugged construction that many users find transformative in both recreational and professional contexts.

Final thoughts

Ultimately, the Cybertruck isn’t just a vehicle; it’s a redefinition of off-roading excellence. With its unique design and advanced features, it offers thrilling performance that resonates with adventurers and enthusiasts alike. Users have shown that this electric marvel can tackle challenges traditionally reserved for fuel-driven pickups while maintaining versatility and comfort. As off-road enthusiasts seek out vehicles that can handle everything from rocky trails to muddy waters, the Cybertruck stands out as an impressive ally ready for adventure. Whether you’re camping deep in the wilderness or bringing tools to your rural property, the Cybertruck is paving a new path in the world of off-road vehicles.