The world of off-roading demands resilience, innovation, and adventure. For enthusiasts looking to tackle the wild outdoors, crafting a capable 2WD off-road truck is a thrilling endeavor. This journey begins with defining your purpose, selecting the right chassis, and harnessing torque-enhanced power that can conquer challenging terrains. As we delve deeper into suspension mastery and tire selection, you’ll gain the essential knowledge to elevate your off-roading experience. Prepare yourself to embrace the rugged spirit that defines true adventurers, as we guide you through each critical phase of your build.

Purpose First: Defining the Mission for a Capable 2WD Off-Road Truck

Defining purpose is the quiet engine that powers every decision in a 2WD off-road build. It is not a mere starting line; it is the compass that keeps the project from drifting toward unnecessary weight, fragile geometry, or a setup that tries to do too much with too little. In a 2WD platform, where only two wheels receive drive torque, the terrain will always test the underlying design with sharper questions than a four-wheel-drive system would. The challenge, therefore, is not simply to stack hardware that looks capable, but to articulate a mission so precise that every component, every layout choice, and every tuning decision aligns with a defined set of use cases. Only then can a 2WD truck deliver reliable traction, predictable handling, and a level of capability that keeps a driver confident on demanding trails, forest roads, or remote work sites where brute force would waste fuel and waste time.

The primary purpose should begin with terrain and tolerance. Will this truck roam light forest trails and rocky paths where traction is moderate but space is tight? Or is the objective more specialized: delivering tools and small loads across rough, remote routes where weight, simplicity, and rugged durability trump raw acceleration? These early distinctions matter because they force a deliberate balance among approach and departure angles, breakover clearance, and ground clearance—the geometric trifecta that largely determines whether a two-wheel drive chassis can keep all four tires engaged on uneven ground. A vehicle built around an explicit mission will trade speed for leverage, and that trade-off is what separates a competent rig from a frustrating one. In this sense, purpose acts as a constraint that channels innovation toward resilience rather than spectacle.

To frame a credible mission, it helps to compare two archetypes without turning the discussion into a catalog of features. The light-duty explorer seeks nimble handling, low maintenance, and efficient operation on mixed surfaces. For such a vehicle, the objective is to maximize the chance that at least two tires remain gripping, even as one encounters an obstacle that momentarily disrupts traction. A well-chosen suspension, tuned for generous articulation, becomes the critical enabler, allowing the chassis to stay level and a tire to stay in contact with the ground. The logistics-focused utility build, by contrast, prioritizes reliability and ground clearance above all else, even if it means a modest sacrifice in ride quality. In that role, the truck may bear protective gear, skid plates, and guard rails that shield vital components from rock and debris, with the awareness that downtime is a cost in remote environments.

Within this framework, the engine and transmission design begin to reveal their true purpose. Low-end torque matters more than peak horsepower, because off-road terrain rarely rewards spin speed when crawling over obstacles. Diesel engines—known for sustained torque at low RPMs—often become a natural fit for 2WD off-road work, where the driver’s appetite for controlled, slow progress is constant. The transmission choice then becomes a dialogue with the crawl: a low-range gear set that multiplies torque to the wheels, enabling controlled progression over steps, ledges, and slick surfaces. Even in a 2WD layout, a thoughtful drivetrain can turn a potential fragility into a predictable characteristic. It is not about overpowering the terrain with sheer horsepower; it is about delivering deliberate, repeatable motion that can be trusted in precarious moments. For a deeper dive into how engine torque and drivetrain planning influence off-road capability, consider the broader discussion on diesel mechanics and how a disciplined, step-by-step approach can improve reliability—an area worth exploring for builders who want to demystify the powertrain choices behind capable 2WD machines. Mastering diesel mechanics—your step-by-step path to success.

Another crucial element is the chassis philosophy itself. A non-load-bearing, body-on-frame configuration offers a robust backbone that can absorb twisting forces without transferring those stresses into the bodywork. This separation between the frame and the body matters most when two wheels are driving and a single obstacle could create a moment that otherwise would distort a more integrated structure. The frame acts like a backbone that flexes where needed and resists bending where it matters most, preserving door alignment, window seals, and overall integrity after repeated impacts. The trade-off is weight and complexity, but for a dedicated off-road crawler or exploration rig, the gains in durability and repairability are often worth the cost. The design justification emerges clearly when you picture a wheel climbing a rock, the frame soaking the twist, and the body remaining square and secure. The result is not just a tougher vehicle; it is a more predictable one, which is the essence of capability in remote environments where assistance is far away.

With purpose established, the next wave of decisions follows: how to allocate mass, how to orchestrate suspension travel, and how to pick tires that can translate the chosen geometry into real-world grip. Suspension articulation becomes the heartbeat of capability. Long-travel configurations—whether coilovers or more flexible leaf setups—maximize the number of contact patches the system can maintain as the chassis angles and the surface irregularities demand more from the tires. This is where the 2WD constraint sharpens the value of every square inch of tire contact. If the rear axle can maintain traction through a sequence of rises and dips, the driver gains confidence to maintain momentum where many would stall. The objective is not to create a limber ride that soaks up every obstacle without consequence, but to retain the ability to keep all four tires in contact while minimizing weight growth and mechanical complexity that would invite trouble in remote settings.

Tire selection then becomes the practical translation of mission into traction strategy. Oversized, aggressive tires will deliver more grip on loose surfaces and better ground clearance, but they also introduce more inertia and rolling resistance. The optimization question becomes: how much tire is enough to bridge the gap between terrain and traction without becoming a hindrance in approach angles or fuel efficiency? Running lower tire pressures on soft ground can further expand the contact patch, yet this must be balanced against the risk of bead-seating issues, sidewall punctures, or loss of control on hard surfaces. A robust approach to tires blends compound choice, tread pattern, and the ability to adjust pressure with a controlled procedure. The driver’s skill enters this stage as a genuine multiplier; a well-informed driver can exploit tire behavior and suspension articulation to climb a difficult ledge, maintain momentum on a rocky grade, or ease through a mud rutted section where a less capable setup might wander and bog down.

The mission then naturally extends to protection and safety. Even a 2WD truck, when faced with sharp rocks or flying debris, benefits from skid plates under critical components, guards for radiators and oil coolers, and a protective framework that can mitigate injuries in case of a rollover. The objective here is not to overbuild, but to anticipate common failure modes and provide a pragmatic shield against them. Protection thinking is part discipline, part realism: you invest in what could stop the truck in its tracks, and you design for field servicing so that a roadside repair is feasible rather than a total loss. In this light, the build becomes a modular statement about reliability under duress rather than a show of brute horsepower.

All of these choices converge on a single uncertainty: where will the vehicle actually operate, and how much risk is acceptable to achieve the mission? The answer guides weight distribution, axle strength, and how the powertrain interacts with the throttle, the clutch or transmission, and the steering system. It also clarifies the testing philosophy. The best-reasoned purpose includes a plan for real-world trials that push the truck through moderate, progressively tougher trails. The aim is to observe wear patterns, listen for unfamiliar noises, and measure how tire wear, suspension preload, and steering alignment evolve under load. As the chassis experiences real terrain, the operations team—whether one builder or a small crew—learns how to adjust tire pressures, tweak suspension travel, and fine tune steering geometry to improve stability and control. This iterative testing is not an afterthought; it is a core activity that transforms a concept into a dependable tool.

In practice, the trajectory from purpose to performance goes through a sequence of disciplined choices. Define the terrain envelope clearly. Decide what the truck must do beyond the obvious need for ground clearance. Choose a chassis approach that tolerates the inevitable twists of the off-road environment. Select a powertrain that delivers torque where it matters most, paired with a transmission layout that amplifies that torque without inviting fragility. Invest in suspension and tires that maximize contact and articulation without dragging weight into the design. Add protective measures that survive the harsh environment. Finally, bake in a testing routine that funds ongoing refinement rather than a single, static build. When these elements align with a well-expressed mission, a 2WD off-road truck becomes more than a curiosity; it becomes a reliable tool capable of exploring the edges of the map while remaining approachable for the driver who values control, efficiency, and predictability over raw, indiscriminate power.

For builders seeking broader context on how purposeful, compact platforms perform in non-military, light-to-medium-duty roles, the study of 2WD mini trucks offers a useful lens. These platforms demonstrate how engineers optimize for on-road use and selective off-road tasks, balancing interior space constraints, driveline layout, and weight distribution to achieve practical capability in everyday environments. This perspective reinforces the central message: a capable 2WD off-road truck is defined first by its mission, and only then by the clever orchestration of hardware that serves that mission with reliability and finesse.

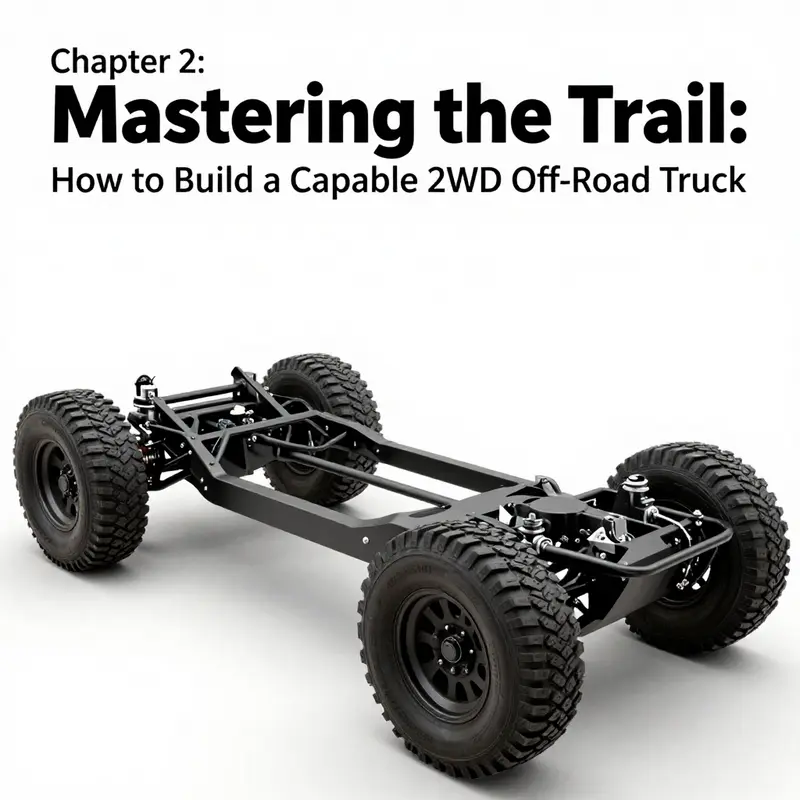

Chassis Fundamentals for a 2WD Off-Road Truck

The chassis is more than a frame; it is the skeleton that dictates how every other system behaves under load, on uneven ground, and through an obstacle field. In a 2WD off-road truck, the chassis must perform a delicate balancing act. It has to be rigid enough to resist twisting when a front wheel loses contact with the ground, yet flexible enough to allow articulation through rough terrain without transferring every vibration directly to the body. It must also support a drivetrain that delivers power to the rear wheels without amplifying torque steer or torque-induced chassis twist. This is where the design philosophy truly begins, because the choice of chassis geometry, material, and integration points filters through to suspension travel, tire contact, traction, and ultimately the driver’s control.

For serious off-road use, a non-load-bearing, body-on-frame configuration — the classic ladder frame — remains a practical anchor point. The frame’s primary job is to take the brunt of twisting forces and impact, preserving the body and interior from deformation even when the truck sits on a jagged rock and one side drops away. The separation between body and frame also makes faults easier to diagnose and repair in remote locations, a crucial factor when you are testing new geometry or upgrading components on a long trail. The frame becomes a robust platform to which upgraded suspension, heavier axles, and reinforced mounting points can be bolted with confidence. Within that approach, the chassis is not a mere skeleton; it is the central module that ties together powertrain, suspension, drivetrain, protection, and ballast in a coherent, serviceable package.

Material choice then becomes a conversation about weight, resilience, and heat. Aluminum alloys bring the advantage of reduced weight and excellent corrosion resistance, which translates into better overall efficiency and improved suspension response thanks to lower sprung and unsprung mass. In high-speed desert runs or long-distance treks where fatigue loads accumulate, the lighter frame helps the suspension work less to keep tires in contact with the ground. Yet aluminum can be less forgiving in high-impact crawls where repeated sharp loads demand ductility and high fatigue resistance. Steel or high-tensile steel frames offer bulkier durability and the ability to absorb and redistribute energy through heavy crossmembers and thick rails. They resist bending and denting in severe rock crawling, but they come with the cost of added weight, which affects acceleration, braking, and suspension forces. Hybrid approaches — steel rails with aluminum panels or composite midsections — are increasingly common when builders want a blend of lightness and strength. It matters less which material is chosen than how the material interacts with the rest of the system: the mounting points must not only survive the abuse but also remain precise enough to keep alignment consistent across suspension cycles.

Alongside material, the geometry and integrity of the chassis rails shape the truck’s real-world performance. A 2WD off roader benefits from reinforced frame rails, sturdy mounting pads for suspension links, and ample ground clearance to prevent body or transfer case contact with rocks during steep climbs. The geometry needs to be chosen with the intended terrain in mind. A longer wheelbase enhances stability on fast, rough desert corridors where high-speed rhythm is the norm, while a shorter wheelbase improves clearance over tight, technical rock trails but can destabilize at speed if not paired with tuned steering and suspension. Track width needs careful tuning as well; a wider stance improves off-axis stability and helps resist rollover on steep side slopes, but too wide a track can complicate obstacle negotiation in tight trails. The wheelbase and track width together influence how the rear axle can load or unload as the front tires search for traction, which is critical when you drive with two wheels getting power at a time and the rear suspension must manage that load transfer without becoming a pendulum under load.

The chassis shown in the explored material is not an abstract ideal; it has practical instantiations in real-world vehicles, and the logic behind those choices translates to RC-scale or full-size builds. Chassis designers in trucks like heavy-duty pickups lean on rugged crossmembers, shock absorbing mounts, and reinforced seat-to-frame connections to damp harmful movements and preserve driveline integrity. Those same principles carry into smaller, non-traditional platform builds wherever the chassis must sustain extended travel, rugged terrain, and unpredictable impacts. In essence, the chassis is a bridge between commanding powertrain capability and the controlled, repeatable behavior a driver needs to survive and prevail in harsh conditions. Even when the end product is an RC-scale machine or a purpose-built trail rig, the same fundamentals apply: a strong, well-integrated frame that respects weight distribution and provides robust anchor points for the suspension and protection equipment.

The discussion naturally touches the broader ecosystem of the vehicle. A robust chassis does not stand alone; it invites a symbiotic relationship with suspension architecture, axle choice, and protection systems. When you prioritize chassis strength and geometry, your suspension can be tuned for greater articulation without sacrificing body integrity. You can fit long-travel coilovers or reinforced leaf springs that maximize wheel contact with uneven ground, while maintaining a predictable, controllable ride. Heavy-duty axles–think robust rear hubs, stiffer gearing, and reinforced housings–anchor the drivetrain under this new umbrella of capability. Protection, too, follows naturally: skid plates become more than optional armor; they preserve the critical transfer paths and vital components beneath the frame, allowing you to pick your line with less fear of sudden damage. Radiator guards and oil-cooler shields protect heat exchangers, a reminder that the chassis and its protection strategies must anticipate the terrain, not merely react to it.

The 2WD approach does not negate these considerations; it reframes them. In a two-wheel-drive configuration where power is directed to the rear, the weight distribution and drivetrain mounting must be intentional. Fewer drive shafts and simpler transfer components can reduce failure modes but place a greater emphasis on the rear suspension’s capacity to manage load and maintain tire contact. The Enduro, cited as a 2WD reference in the broader discussion of capable platforms, demonstrates how strategic power distribution and independent drive mechanics can compensate for limitations in wheel torque or drive layout. While the Enduro is a motorcycle, its lesson is transferable: with a carefully engineered geometry and articulate rear suspension, a 2WD system can remain surprisingly capable in harsh conditions if the chassis acts as a stable, forgiving platform that keeps tires gripping and the driver confident.

Putting these ideas into practical terms means starting from the use case and letting the chassis design follow. If your goal is casual trail riding with occasional technical sections, a lighter aluminum chassis tied to a strong, integrated suspension system can deliver a nimble, responsive feel with respectable durability. If the mission profile includes aggressive crawling and extended bass line trials through rough terrain, a steel or hybrid chassis with reinforced crossmembers, substantial mounting points, and a disciplined approach to weight distribution will resist fatigue and deformation under repeated hammering. In either case, the chassis should be treated as a design parameter with the same seriousness as engine choice or tire selection. You should examine how the chassis will handle torque input, how it will accommodate articulation, and how it will support protection features without overly constraining the suspension.

The process is iterative. Start with a concept that aligns with your terrain profile, then model anticipated load paths across wheel travel. Check for pinch points where components could clash, and verify that the frame rails have enough clearance to avoid interference during full articulation. Plan the mounting strategy for the suspension that maximizes tire contact on uneven surfaces, not just at rest. As you refine, keep a clear eye on maintenance and repairability; one of the often overlooked advantages of a sturdy, modular chassis is the ease with which you can upgrade sections or replace failed components on a remote trail. The end result should be a chassis that boots traction into the ground with clarity and confidence, letting the driver concentrate on line selection rather than wrestling with chassis flex or unexpected body contact.

For readers seeking a deeper dive into how material choices influence chassis performance, a practical exploration of chassis science offers complementary insight. A practical reference on the science behind chassis properties and their production can broaden your understanding of how to select the right frame for your application. To expand on the mechanics that underpin these choices, see Mastering Diesel Mechanics. It links the powertrain integration decision-making to robust chassis design, illustrating how a reliable drivetrain and a strong frame together form a coherent, durable off-road system. For a broader, foundational look at chassis properties in off-road contexts, consider the external resource that surveys chassis design in RC and full-size platforms: https://www.rcuniverse.com/article/the-science-behind-best-rc-car-chassis-properties-production-and-applications.html. This cross-disciplinary perspective helps illuminate how the same concepts play out across scales and disciplines, reinforcing the idea that the chassis is the decisive hub around which all other off-road performance revolves. As you move toward building or refining your 2WD trail machine, keep the chassis at the center of the conversation, every choice feeding into a more capable, reliable, and rewarding ride.

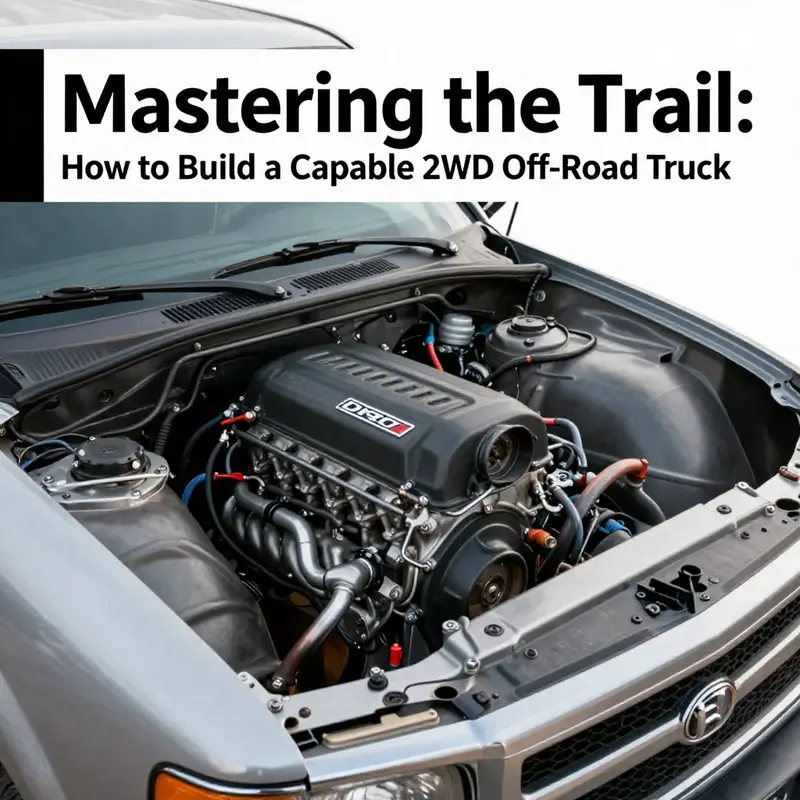

Harnessing Low-End Torque: How Torque-Enhanced Systems Make a Capable 2WD Off-Road Truck Come Alive

A two-wheel-drive off-road platform gains its real edge not from sheer top speed or horsepower but from the way it delivers power down low. In rocky climbs, loose dirt, or uneven ground, the ability to push a vehicle forward without excessive wheel spin is the difference between a confident line and a stalled struggle. This chapter centers on torque-enhanced systems — the deliberate shaping of power delivery, gearing, and chassis dynamics so a 2WD setup can bite hard where it matters most. It is a practical philosophy that harmonizes the core choices outlined earlier: purposeful geometry, a robust chassis, and a articulation-focused suspension. The core idea is simple: you want grip-first torque, managed through components and tuning that keep the drive wheels firmly planted while you steer with finesse and throttle discipline. In practice, that means prioritizing low-end torque, predictable throttle response, and an energy delivery profile that favors traction over raw rush. When the terrain bites, a well-tuned torque system keeps the wheels turning and the truck moving, rather than spinning uselessly in place or stalling at the foot of a rock face. This approach is particularly powerful for 2WD builds, where you intentionally trade some ballast for simpler, lighter weight and fewer failure points. Yet the gains come from a careful assembly of three interlocking domains: powertrain physics, drivetrain robustness, and the tire-contact interface. Begin with power delivery, then tune the machine around it, and finally validate through deliberate on-trail testing and iterative refinement.

The first pillar is the powertrain, where the intent is to convert engine or motor torque into usable motion at the wheels with minimal loss and maximum control. In a traditional 2WD framework, this translates to a torque-rich character that surges at low speeds rather than a sudden rush at mid to high revs. For internal-combustion equivalents, that means a torque-strong engine paired with a transmission or gearing setup that emphasizes a usable crawl ratio. In an electrified or brushless context — whether in hobby-scale models or concept-off-road rigs — the same principle applies, but the realization shifts toward motors with low KV ratings and gear trains engineered to translate high stall torque into forward motion without abrupt wheel slip. Specifically, low KV brushless motors (in the approximate range of 1500–2500 KV for many applications) are optimized to deliver substantial torque early in the rotation, a critical attribute for crawling and climbing. The motor choice does not stand alone; the belt, gear, or chain train and the final drive must be a matched system. You want a robust gear set that resists stripping under shock while maintaining a predictable torque curve. Materials matter here: steel or titanium alloy gear sets often win for their durability, especially when you are crawling over jagged rocks or negotiating abrupt transitions between surfaces. The goal is not to punish the drivetrain with torque you cannot reliably transfer; the goal is to shape the transfer so that every watt available in those low RPMs is used efficiently.

The second pillar is the drivetrain architecture and gearing philosophy. In a 2WD chassis, the suppression of wheelspin hinges on how aggressively you multiply engine torque before it reaches the wheels. If you imagine a crawl ratio as a single, governing figure, the higher, the easier it is to inch through obstacles at a controlled speed. That means choosing transmission and gearing that give you a low-range feel — even if you are not running a full four-by-four. The reality is that without a transfer case, you still can tune the system to deliver substantial low-speed torque. A single-speed or stepped transmission can be fine if it is engineered with tight clearances and strong tooth engagement. What matters is the drive ratio placed between engine torque and wheel torque when the vehicle is in challenging conditions. Differential tuning also plays a crucial role. A biased differential approach helps to manage traction transfer between wheels that are clutching in and out of grip. In practical terms, you want a setup that reduces wheel spin on slick rock and mud while avoiding brutal torque swings that destabilize the chassis. Fine-tuning may involve differential presets, plate thickness, or lightweight recoupable friction components — adjustments that give you smoother engagement and more sustained grip through irregular terrain. This is where the design philosophy dovetails with the driver’s skill: a controlled throttle, a deliberate line, and a willingness to let the suspension do its work while the drivetrain keeps a firm, steady pull.

The third pillar concerns energy delivery and the broader energy architecture of the vehicle. A torque-enhanced system, especially in an electrified or hybridized interpretation, relies on energy storage and delivery that support sustained pull through long climbs and rough sections. For RC-scale or concept off-road applications, a higher-capacity energy pack — such as a larger LiPo configuration — helps maintain consistent current and reduces voltage sag during heavy loading. In real-world vehicles, this translates to a powertrain and fuel system calibrated for a broad, flat torque curve across the relevant RPM range. The objective is continuous traction rather than bursts of torque that quickly dissipate. The energy strategy must also consider weight distribution. Placing energy storage centrally and as low as possible improves the vehicle’s ability to use torque without disturbing steering and weight balance. While this discussion leans toward a generalized, cross-domain view, the principle remains the same: torque is only valuable when it can be transmitted to the wheels in a controllable, predictable fashion.

Tuning is the bridge between theory and trail. This is where you translate the torque-rich intent into a ride that feels responsive without being touchy. Differential settings matter here, as does the suspension geometry. A well-tuned suspension keeps tires in contact and mitigates the chance that a roaring torque push will cause a wheel to unload and spin. The suspension also sets how the chassis translates the power into forward motion through complex terrain. If the springs are too stiff, you will launch over rocks and lose contact; if they are too soft, you will squat and wallow, bogging down the traction you have fought so hard to achieve. The ideal is a balanced articulation that allows each wheel to find grip as the terrain shifts beneath it. In practice, this balance shows up as a suspension with enough travel to keep tires on the ground on irregular surfaces, plus adjustable dampers that let you tune how quickly the system reacts to impact and how it recovers between obstacles. Tire choice is inseparable from this equation. Aggressive tread patterns and larger diameters enhance rough-terrain grip, but they only unlock their full potential if the suspension can maintain stable contact patch loading. Tire pressures are not a one-and-done parameter; they must be revisited as you encounter different surfaces, from compact dirt to loose sand and jagged rock. The objective is simple in concept: maximize the time each tire stays gripping the surface, which in turn maximizes the effective crawl speed of the entire truck.

The practical outcome of this integrated approach is a 2WD truck that behaves like a more capable 4WD in the right conditions, but with the simplicity and lightness that 2WD affords. You gain the benefit of reduced mechanical complexity and fewer potential points of failure, provided you have engineered the interface between power, drive, and grip with intention. It is not about forcing maximum speed through rough sections; it is about maintaining forward momentum with composure, using torque as a tool to stay connected to the ground. For drivers, this translates into a more forgiving yet capable machine. You learn to read the terrain and manage torque with smooth throttle modulation, letting the suspension do the heavy lifting while the drivetrain handles the power distribution. The synergy between low-end torque, resilient gearing, and careful tire selection is what transforms a basic 2WD platform into a capable explorer — one that can negotiate rocky ledges, shallow ruts, and clay-rich climbs without relying on a four-wheel-drive system.

As you consider future upgrades, you might ask how this torque-centric approach translates to broader power networks, including electrified systems. A practical, forward-looking thread ties back to the idea that energy delivery and powertrain architecture determine how effectively you convert energy into traction. If you are exploring electric propulsion in a 2WD off-road platform, study how energy storage and power electronics interact with the motor torque curve. In that vein, you can explore resources that discuss charging infrastructure and energy delivery in rugged applications, which can inform how you design your system for reliability and safety. For a concise look at electrified charging frameworks relevant to rugged vehicles, explore electric-fire-truck-charging-infrastructure. This kind of cross-pollination helps you future-proof your build while staying grounded in the practicalities of torque engineering today.

For a deeper dive into technical refinements and community-tested strategies, the RC community, in particular, has long emphasized the importance of matching motor Kv, gear ratios, and battery chemistry to the terrain, including how to mitigate wheel spin and maximize traction transfer under high load. A well-regarded, in-depth reference for 2WD torque optimization can be found in discussions on RC groups, which collate practical experiments, tuning notes, and long-term wear data. See RC Groups for detailed technical insights into enhancing 2WD RC truck performance: https://www.rcgroups.com/forums/.

In summary, a torque-enhanced system for a 2WD off-road truck is a deliberate orchestration of three forces—the physics of power delivery, the robustness of the drivetrain, and the finesse of chassis tuning. When aligned, these elements deliver controlled, confident traction across the most demanding ground. The driver remains in command, using throttle as a precise tool to maintain grip while the suspension and tires maintain contact. The result is a 2WD platform that can tackle serious terrain with the reliability and joy that come from thoughtful engineering rather than brute force alone. The journey from concept to trail is iterative. Each outing reveals where grip is won, where weight shifts, where damping falls short, and where the powertrain needs smoother, steadier support. With time, a well-tuned torque-enhanced 2WD truck becomes less of a compromise and more of a deliberate, capable partner on the trail.

External resource note: For detailed technical insights into enhancing 2WD RC truck performance, including motor selection and drivetrain optimization, refer to RC Groups: https://www.rcgroups.com/forums/.

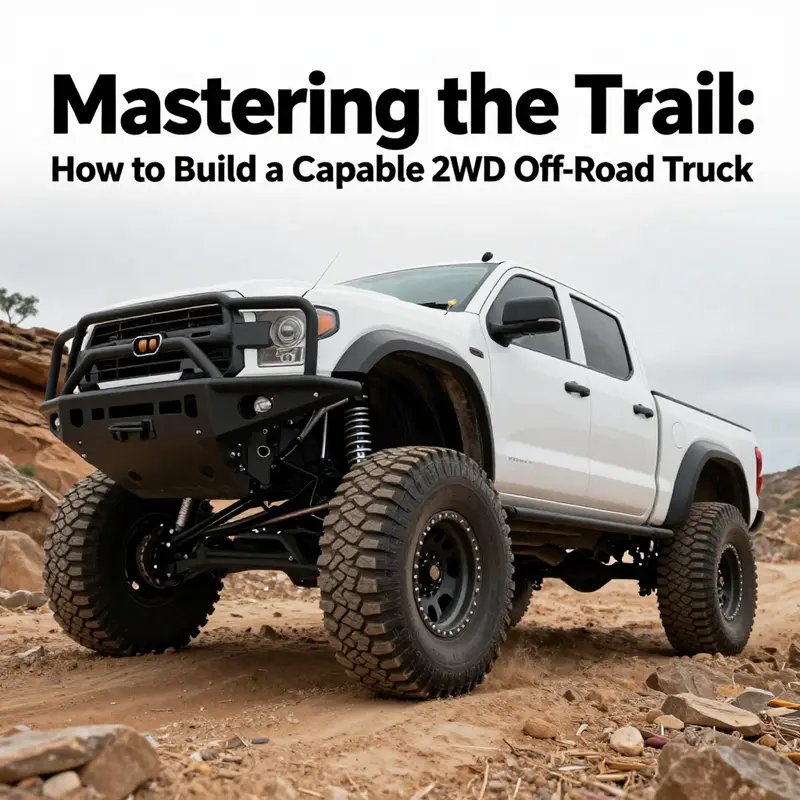

The Backbone and Grips: Elevating a 2WD Off-Road Truck Through Suspension Mastery and Tire Strategy

A two-wheel-drive platform can surprise you on rough trails when you give it a backbone and a set of grips that behave like a true off-road machine. In the world of rugged terrain, the chassis and powertrain begin to shine only after the suspension and tires take over the work of turning power into controlled motion. This chapter threads together the practical realities of upgrading a 2WD setup with a thoughtful suspension philosophy and a tire strategy that maximizes traction, stability, and ground clearance. It treats the suspension as more than a ride height adjustment and the tires as more than a choice of tread pattern; they are the primary interfaces with the terrain, dictating what the truck can crawl over, what it can float across, and how predictable it remains when the surface suddenly changes from smooth clay to jagged rock. The aim is not to chase brute horsepower, but to cultivate throughputs of grip, geometry, and control, so a capable driver can place the truck where needed and in a way that keeps momentum without compromising safety or reliability.

Long before the first wheel meets the trail, the design question centers on how the suspension geometry interacts with a 2WD drive layout. A lift, for example, is not a toy for making the truck look tall; it is a deliberate choice that alters approach and departure angles, undercarriage clearance, and the geometry of the rear axle relative to the chassis. A modest 2-3 inch lift often brings meaningful gains in clearance and angles without overstraining steering components or driveshafts. But as the lift climbs past about 3 inches, the complexity multiplies. Longer control arms, modified steering geometry, extended driveshafts, and potential interference with brake lines and exhaust routing become real considerations. The best practice is to view lift as a platform change rather than a cosmetic tweak, and to approach it with a plan for alignment, steering effort, and safe handling at speed.

In parallel, the suspension’s damping system sits at the heart of articulation and tire contact. Stock dampers often prioritize on-road comfort and predictable behavior on smooth surfaces, which translates to limited wheel travel and less grip on uneven ground. Upgrading to heavy-duty, adjustable shocks gives you the ability to tune how the system responds to rocks, ruts, and sudden changes in terrain. High-quality shock absorbers—often a twin-tube or reservoir-equipped design from established manufacturers—offer superior bottoming resistance and better control of body roll. In off-road use, the goal is to keep all four tires in contact with the ground as much as possible, even when a corner is arcing over a rock step or a wheel drops into a deep rut. Adjustable damping lets you tailor the system for a given terrain: firmer settings to minimize chassis pitch on rough, tram-laden surfaces and softer settings to maximize wheel travel where the surface is forgiving but uneven.

The role of sway bars in this context is subtle but crucial. A front sway bar helps keep the vehicle stable during cornering, reducing excessive body roll that can hinder steering feel and tire contact. In more extreme scenarios, many off-road builders disconnect the rear sway bar to increase articulation. The idea is simple: more articulation means more tires on the ground, which translates into more traction. However, full articulation can compromise on-pavement stability, steering response, and load transfer during braking. The balancing act is to retain sufficient rigidity for predictable behavior on the street while allowing generous, controllable movement off-road. In some builds, reinforcing the frame with cross-bracing becomes a wise precaution when the suspension is coaxed into large-movement regimes. The frame becomes the backbone that resists flexing and preserves alignment under load when you’re crawling over massive rocks or negotiating a step-down at slow speed.

Tire choice is where your suspension philosophy meets the terrain directly. Tires are the sole contact between the truck and the ground, so their design governs grip, flotation, wear, and, ultimately, the speed at which you can negotiate obstacles. Size matters, but not in a vacuum. A larger diameter tire yields higher ground clearance and a larger tread footprint, which helps you float over soft surfaces like sand or mud and reduces ground pressure. Wider tires spread weight more evenly and can improve traction on soft terrain, but they can also rub against fenders and increase rolling resistance on pavement. The art is to select a size that fits the wheel wells without rubbing, and, if necessary, to adapt fender liners or install fender flares to maintain clearance. The tread pattern choice is a more nuanced decision. All-Terrain tires strike a balance between on-road daily usability and off-road capability, delivering solid traction across gravel, mud, and light rock while keeping noise and ride comfort reasonable. Mud-Terrain tires, by contrast, reveal their strength in deep mud, soft sand, and highly technical trails. They are aggressive and excellent at self-cleaning but come with more road noise, a stiffer ride, and faster wear on pavement.

Pressure management is a topic that often doesn’t receive enough attention but has outsized effects on traction. Lower tire pressure increases the contact patch, which helps the tire bite into soft surfaces and maintain grip on loose rock and sand. A common starting point for soft terrains is to drop from road pressure into a range of roughly 18-20 psi, with cautious experimentation to avoid bead off or sidewall damage. The trade-off is immediately apparent: more grip off-road but a requirement to reinflate the tires for highway use to protect fuel economy, steering response, and tire wear. A compact, portable air compressor becomes an essential companion, allowing the operator to tailor the tire pressure to terrain in near real time as the trail changes. Tire pressure management, in concert with suspension articulation, determines how smoothly the truck can ride over a boulder field, how easily it can float across wet grass or loose sand, and how stable it remains when the surface suddenly transitions to a gravel road or a steep, slippery slope.

To bring these elements together into a coherent 2WD off-road package, consider the driver’s role in managing traction. In a 2WD system, the rear axle often handles propulsion and can be configured most effectively to maximize traction with the right tire choice and a suspension that ensures the rear tires can stay planted. A well-sorted rear suspension that minimizes axle wrap, combined with a tire lineup that prioritizes grip and float, will enable the truck to crawl up and over obstacles that would bench mark a less prepared vehicle. The physics of weight transfer play a pivotal role here. When you tackle an incline, you want a system that maintains a favorable weight distribution across the driven wheels. Excessive squat or rear-end dive can unload the tires precisely when grip is needed most, so the suspension must manage dive, squat, and anti-squat with an eye toward maintaining tire contact and predictable steering inputs. In practice, this means stiffer, well-tuned rear dampers, a solid, rigid chassis that resists twisting, and a careful approach to lift height that does not push the geometry beyond the point where steering and braking become compromised.

The optimization process is iterative. Start with a conservative lift, a robust set of shocks, and a tire choice that matches the terrain you expect to encounter most. Test on mild trails to establish baseline behavior: how does the truck handle slow crawls, how does it respond to steering input when a tire drops into a rut, and how does the weight shift when power is applied from the rear? Record these observations and adjust tire pressures, damping settings, and, if needed, sway-bar engagement. If the tires are consistently losing contact with the ground on a given obstacle, you might benefit from a small increase in rear spring rate or a change to a shock with slightly different rebound characteristics to keep the wheel planted during rebound. If the vehicle feels overly stiff and transfers bumps directly into the cabin, a softer setting or a rebalanced suspension could improve controlled articulation without abandoning ground clearance.

It is worth remembering that the story of a capable 2WD off-road build is not one of hardware alone but of integration. Every component, from the maxi-travel coilovers to the tire pressure gauge, must be chosen with the others in mind. The geometry changes introduced by lifts affect steering effort, brake response, and drivetrain angles. The suspension must be compatible with the intended axle geometry, the driveshaft angles, and the potential for vibrations at speed. The tires must be selected not just for traction but also for how they contribute to the vehicle’s overall mass distribution and how they respond to heat build-up under load. In a 2WD layout, any drag or inefficiency in the tires translates directly into the rider’s experience of the trail, because there is no second driven axle to compensate for a shortfall in traction.

The practical path forward, therefore, is a measured, tested approach. Begin with a clear map of the terrain you intend to conquer and the load you expect to carry. Build the suspension around that map so that ground clearance and articulation serve the same purpose: keeping tires in contact with the ground and delivering predictable steering under load. Choose tires that can perform across a spectrum of scenarios—sand, mud, rocky trails, and wet pavement—with minimal compromise. When you adjust air pressure for soft surfaces, monitor how the vehicle responds to changes in weight transfer, and be prepared to recalibrate the suspension damping to maintain stability. These adjustments should feel intuitive after a handful of controlled trials, not after a single conversion. The beauty of a well-tuned 2WD off-road truck lies in the seamless rhythm between chassis rigidity, tire grip, and driver input; it is a choreography where suspension and tires do the heavy lifting, while the driver provides the precision and pace needed to traverse demanding terrain.

For readers seeking a broader context on powertrain basics and how engine performance intersects with off-road capability, a practical reference is available in the broader diesel mechanics literature. While this chapter centers on suspension and tires, understanding the engine’s low-end torque and how it interacts with a crawl ratio helps ensure you don’t create a bottleneck that undermines traction. You can explore a structured diesel mechanics guide that walks through fundamentals and fault-finding in a step-by-step path to success. mastering-diesel-mechanics-your-step-by-step-path-to-success.

All told, elevating a 2WD off-road truck from a daily driver to a capable trail companion hinges on giving the suspension the ability to articulate and maintain tire contact, and on selecting tires that maximize grip across the terrain you intend to conquer. The lift height should be a considered balance between ground clearance and the integrity of steering and braking geometry. The shocks should be tunable to the ride you want, and the sway bar strategy should reflect your willingness to trade on-road composure for off-road flexibility. When these elements are aligned with a driver’s skill and a disciplined testing routine, a 2WD truck is not merely adequate for light excursions; it becomes a deliberate tool for exploring technical trails that demand patience, control, and a measured approach to momentum. In practice, this means you move with intention on the trail: watching tire contact, listening for the telltale signs of axle wrap or driveline strain, and adjusting pressure, damping, and alignment until the truck responds to your inputs in a calm, predictable way. The result is a vehicle that can glide over rough terrain with confidence, where grip, clearance, and clever geometry keep you moving when others may hesitate. And in that sense, suspension mastery and tire strategy are not luxuries; they are the core craft of turning a capable 2WD into a credible off-road partner for the long, rocky haul ahead.

External resource: https://en.wikipedia.org/wiki/Off-roading

Final thoughts

Transforming a standard pickup into a formidable 2WD off-road truck is a journey that requires vision, knowledge, and dedication. By understanding your desired terrain, choosing a robust chassis, harnessing the right powertrain, and investing in performance enhancements, you create a vehicle that stands out in any adventure. Each aspect we’ve covered is vital, reflecting the spirit of off-roading that champions adaptability and resilience. As you embark on this build, remember: it’s not just about getting from point A to point B—it’s about enjoying every wild turn along the way and pushing the limits of what’s possible.