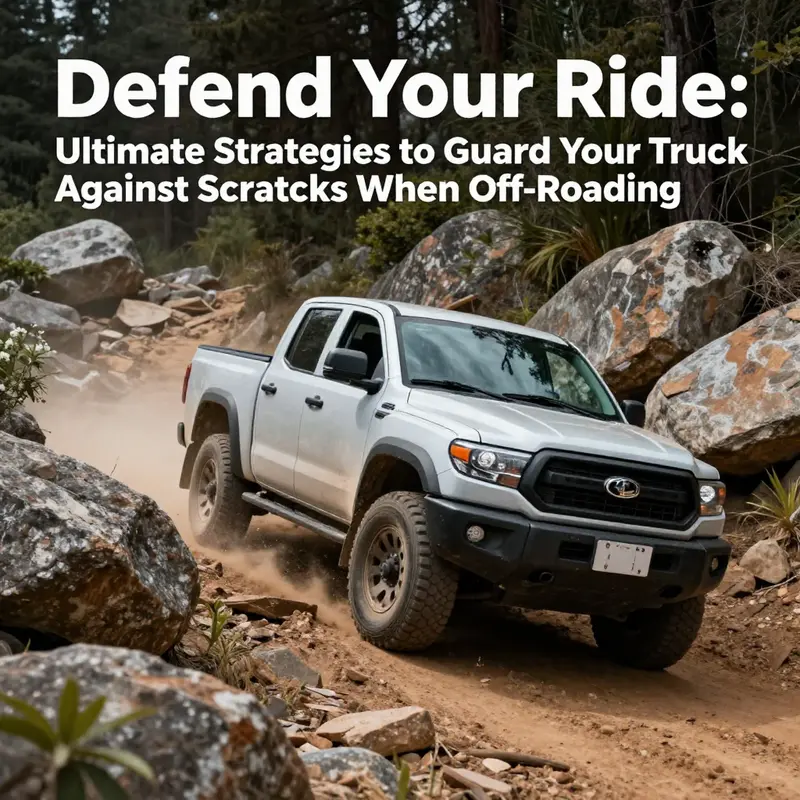

Off-roading is a thrilling adventure that calls for both skill and preparation. But the rugged terrains that offer excitement also pose a significant risk to your truck, from scratches to serious body damage. For off-road enthusiasts and adventurers, protecting your investment is crucial. This guide outlines comprehensive strategies to safeguard your truck from the harsh realities of off-road environments. We’ll explore the importance of protective coverings, meticulous inspections before trips, wise routing decisions, cautious driving, and diligent post-trip maintenance. Each chapter equips you with actionable insights to ensure your truck remains in top condition, allowing you to embrace the wild terrains without compromising on style and safety.

Guarding the Trail-Wear: How Protective Coverings and Skid Plates Shield Your Truck from Scratches on Off-Road Adventures

Protecting a truck on rough trails isn’t a single shield; it’s a philosophy of layered defense. Exterior coverings battle rocks, branches, and grit, while undercarriage protection keeps the drivetrain and essential components safe from sharp terrain. When these two strands work in harmony, you reduce the chances of visible scratches, paint chips, and costly underbody damage. The best protection starts with thoughtful preparation, the right materials, and disciplined driving about how and where you choose to ride. This approach isn’t about turning off-roading into a static showroom experience. It’s about preserving your truck’s utility and resale value so you can return to the trail again and again with confidence. The underlying principle is simple: disrupt the chain of impact before it reaches the most vulnerable surfaces, and you’ll minimize the long‑term wear that scratch-prone trails tend to introduce. The practical path forward blends proven materials with careful maintenance, and it rewards the rider who respects the environment and the machine in equal measure.

Protective coverings form the first line of defense. These are not cosmetic add-ons; they act as a dedicated barrier between the paintwork and the world outside the fenders. For off-roading, you want a cover that is custom-fit, breathable, and weather-resistant. The emphasis is on a material that can bend and flex with the body without lifting or bunching, while still blocking rocks, branches, and other trail hazards. Thermoplastic polyurethane (TPU) is a standout in this category because of its combination of elasticity, abrasion resistance, and a measure of self-healing capability. A cover made from a TPU-like material can absorb minor scuffs and recover enough to preserve a smooth exterior surface. A breathable design matters too; it allows airflow under the cover to prevent moisture buildup that could trap mud or cause rust over time. The goal isn’t to seal the truck away from the world but to create a controlled layer that reduces friction and micro-scratches as you slide over rocks and through brush.

Another feature to consider is the fit. A custom-fit cover respects the contours of your truck’s panels, doors, and grooves, reducing flapping and flutter at highway speeds or on fast-rolling trails. Loose or generic coverings can flap in the wind, trap grit, or loosen at inopportune moments. In the worst cases, a loose cover can act like sandpaper against the paint when the truck shifts on a slope. Proper use also means cleaning the vehicle thoroughly before applying the cover. Dust, mud, and grit trapped between the cover and the body can grind away at the finish as the vehicle shuffles during the ride. The result is not an immediate scratch but a slow, cumulative abrasion that becomes visible after several trips. A simple rule of thumb is to prepare, protect, and then reassess after each trip.

Paint protection films (PPF) and clear, body‑colored wraps are common companions to TPU covers. These films add yet another layer of defense against chips from flying stones and tree debris. The film should be selected with proper UV resistance and clarity to keep the original look intact while delivering practical protection. The science behind film protection is straightforward: a tough, transparent layer disperses impact energy and keeps the paint from contacting the inevitable trail debris. What matters in practice is the installation and maintenance. Have the edges sealed and the film inspected regularly for lifting or micro-tears, especially around edges, doors, and curves where stress concentrates. If any wear appears, a professional refresh is often the most cost-effective choice over a large, ongoing patchwork of DIY fixes.

In many off-roading circles, the undercarriage bears the brunt of harsh terrain. Skid plates are the second thrust in the protective plan. These rigid shields are typically fashioned from high‑strength steel, aluminum, or composite materials and bolt directly to the frame. Their purpose is blunt and clear: prevent contact between the most vulnerable underbody components—engine oil pan, transmission, differentials, fuel system, and suspension hardware—and the ground. Skid plates reduce the risk of gouges, punctures, and leaks that can interrupt a trip or demand expensive repairs. They don’t just save parts; they give the driver confidence to tackle steeper, rockier, or more uneven trails because that nagging worry about a rock the size of a football grinding into the oil pan becomes a manageable risk, not a certainty.

The best protection comes from combining these layers. A well‑protected truck has a custom-fit, breathable exterior cover to guard the paint and a full set of skid plates to shield the undercarriage. The integration matters: the cover should not trap debris that can abrade high‑contact zones when the truck moves, and the skid plates should not interfere with ground clearance or create additional snag points. Regular inspection is essential—after every trip, check the cover for tears, loosened fasteners, and edge lifting, and inspect the skid plates for dents, loose bolts, or gaps. A quick preventative check after each outing can stop a minor issue from becoming a major repair in the shop.

Beyond the immediate protection, the mindset of use matters. For example, a deliberate approach to route planning reduces the exposure of vulnerable surfaces to the most corrosive or abrasive obstacles. Slower speeds on rough sections reduce the impact energy that ultimately travels through the protective layers and into the body panels. When obstacles are encountered, approach at a slight angle rather than perpendicular to the surface, lowering the contact area and the likelihood of a broad, straight scrape along a door or fender. Overhanging branches and tight corridors demand careful line selection; a cautious, methodical pace preserves pristine finishes and deferred maintenance costs. While these principles are simple in theory, they translate into significant savings in paint and metal over the long haul.

For readers who want a broader mechanical perspective on how protective systems fit into overall vehicle care, a deeper dive into the mechanics behind durable covers can be found here: Mastering-Diesel-Mechanics: A Step-by-Step Path to Success.

In the end, the goal is to keep the truck looking as good as it runs. A routine that blends selective, high‑quality coverings with sturdy underbody protection and sensible driving practices brings durable results. It may require an upfront investment, but the payoff is straightforward: fewer scratches, less downtime for repairs, and preserved resale value. After each outing, a clean, careful reapplication of protection and a quick undercarriage check create a sustainable rhythm. The vehicle that leaves the trail with the same finish it arrived with is not just luck; it is the product of deliberate protection, consistent maintenance, and a patient respect for the terrain. For those who treat protection as a continuous practice rather than a one‑time install, the off-road experience stays adventurous without becoming a ledger of bodywork costs. And when the miles add up, the truck still looks ready for the next ride, the next challenge, and the next wash afterward.

External resource for further material science context on exterior coverings and their performance on scratches and abrasions can be found here: https://www.caranddriver.com/features/a58264197/tpu-vs-pvc-car-covers-which-is-better/.

Pre-Trip Inspections as Armor: How a Thorough Check Shields Your Truck from Scratches on Off-Road Trails

On rough trails, the difference between a day of triumph and a day spent nursing scratches often boils down to what you do before you turn the key. A thorough pre-trip inspection does more than verify function; it acts as armor for the truck’s exterior, spotting vulnerabilities before they become bite marks on paint or metal. The walk-around becomes a quiet ritual, a protective habit that keeps you mindful of how the trail will interact with every panel, fastener, and crevice. When you approach the vehicle with routine, calm attention, you learn to expect resistance from the trail and to meet it with measured steps rather than reckless momentum.

Begin with wheels and tires, the first line between you and the terrain. Check inflation not only to the manufacturer’s spec but for the grade of trail you expect. A tire too soft on a sharp rock face can overheat and suffer bead damage; too hard, and it slips on loose rock, inviting scrapes. Inspect tread wear; uneven wear signals alignment or suspension issues that can translate into fender scuffs on a tight line. Look for embedded rocks, gravel, or mud in the tread that can chip or pinch. Examine sidewalls for bulges, cuts, or cracking; a compromised sidewall can fail suddenly, leaving you stranded and facing cosmetic and structural costs.

Next, move along the lower body panels, bumpers, fenders, and rocker panels—the zones most exposed to spray, brush, and rock. Even a small dent or chip can become a focal point for cracking paint in rougher terrain. Before departure, note any existing blemishes so you can monitor them. If you anticipate aggressive terrain, consider applying protective film to vulnerable edges; a clear shield can shield paint from minor scrapes that accumulate with miles of sand and shale. If you already use underbody protection, give those pieces a visual check too—the fasteners should be tight, and guards should sit flush without wobble that could catch on a rock or root.

Underneath, the undercarriage deserves equal scrutiny. Loose bolts or damaged skid plates are not cosmetic issues; they invite dragging and bigger scrapes. Look for frayed wiring, loose brackets, or rubbing points where rocks press a cable into a sheath. Inspect the suspension and steering components for play that could translate to sudden contact with obstacles. If guards are present, ensure they are securely mounted and that clearance will not change under load. A careful undercarriage check sets the tone for the day, reducing the chance of a new dent along a rock shelf.

Then turn to fluids and overall readiness. Verify engine oil, coolant, brake fluid, and transmission fluid sit at proper levels for the day’s duties. Low levels can force stops in awkward places, while overheating multiplies the risk of damage and paint fade. A quick look should reveal leaks, which, if present, demand repair or a plan for safe service. The goal is not perfection but to ensure no hidden failure will catch you in a moment when appearance matters most.

Exterior visibility matters as much as exterior protection. Check that all lights work and are protected by rugged covers. Wiper blades should clear in mud and spray, leaving your view unclouded. If you carry additional lighting for night driving, ensure their wiring is secure and lenses are protected from minor impacts that could crack glass on the trail.

With the mechanicals checked, the next layer is route awareness. Pre-trip checks feed into choices about where to go and how to go there. You’ll combine the knowledge from tires, guards, and undercarriage with a trusted map or off-road app to chart a path that minimizes exposure to dense brush, sharp rock faces, or overhanging limbs. The pre-trip mindset is not fear but informed caution. You learn to slow down where a straight line invites contact and to seek lines that roll over obstacles while keeping the body within a safe envelope. Momentum still matters, but it becomes a controlled tool rather than a reckless impulse.

Beyond the routine, perception matters. If a trail looks likely to rub, you may divert rather than push, accepting the longer route as a smart protective habit. The pre-trip routine feeds into decisions about protective measures—films, sliders, and armor—because the wiser you are about what is likely to contact the vehicle, the less you will answer to a trail that answered first. The aim is to keep the truck near factory condition without hindering an adventurous drive. This balance is not about shutting down exploration but about choosing routes and speeds that let you enjoy the ride and maintain surface integrity.

As the drive ends, the loop completes. The discipline you built guides how you clean and inspect after the run. A thorough wash removes mud that can trap moisture and abrade finishes. While you rinse, scan for new scratches or chips that deserve touch-up or film reapplication. Replacing torn clips, tightening fasteners, and refreshing protective layers become routine maintenance rather than a crisis response. The result is a truck that remains resilient on rough trails and a driver who treats marks as signals to protect and repair.

With this routine, you approach trails with confidence, knowing that minor slips won’t ruin your weekend. The pre-trip inspection is your first line of defense against unwanted surface marks and it aligns with the larger strategy of using protective film, proper route planning, and disciplined driving.

External resource: https://www.motortrend.com/offroad/truck-pre-drive-checklist/

Trailwise Route Selection: Protecting Your Truck from Scratches Through Smart Off-Road Planning

Choosing a route on rough terrain is more than a preference; it’s a tactical decision that shapes every mile you cover. The body of your truck is a magnet for scrapes when you push through tight brush, slide along rocky ledges, or edge past awkward obstacles. The smartest way to reduce that risk starts long before you strap in and turn the key. It begins with how you pick the trail itself. Established, clearly marked routes that match your vehicle’s capability create a built-in boundary between adventure and avoidable damage. Trails that have been rated for difficulty provide a framework within which you can gauge what your truck can handle without inviting unnecessary contact with rocks, branches, or rutted surfaces that can gouge paint or bend panels.

Hazards are rarely obvious at the trailhead. Deep ruts can hide a sharp rock just beneath the surface, and a steep incline can force you to squeeze too close to a shoulder or a tree line. Narrow passages widen the risk of side contact with brush or undercarriage components. When route scouting, you’re not merely looking for a path that exists; you’re scanning for the little frictions that become big scratches once momentum carries you into them. This is where the combination of maps, GPS, and local knowledge becomes essential. Maps and off-road mode on navigation apps help you visualize the terrain ahead, while local riders or guides can warn you about recent trail changes, erosion patterns, or fallen branches that aren’t yet reflected on digital charts. The goal is to arrive with a mental map of the potential pinch points and plan a path that minimizes contact while still preserving momentum to keep the ride smooth and controlled.

Scouting ahead also means recognizing when a route is suddenly unsuitable for your vehicle. A trail that looks manageable on a broad map may conceal a section with loose scree, wet clay, or a rock shelf that invites a scrape on the rocker panel or a dent in the fender. It’s not about cowardice; it’s about prudence. If you identify a hazard that would demand aggressive steering, an abrupt maneuver, or too close proximity to a fixed object, it’s wise to pivot to a safer line. This is where the technique of driving at a deliberate, deliberate pace becomes a key tool. Slower speeds grant longer reaction times and a more accurate read of how the tires grip and where a wheel might kiss a rock edge or brush against low-hanging branches. Momentum, when misapplied, can force you into a reactive moment you didn’t anticipate. Momentum, when used with discretion, helps you roll over obstacles with a measured nudge rather than a violent impact that leaves scratches and, worse, misalignments.

The approach to obstacles should be measured and calculated. When you encounter a boulder, a log, or a stump that could threaten the underbody, aim to approach at a slight angle rather than head-on. A diagonal line plus careful throttle control often reduces the amount of body contact and distributes any minor hits away from doors, fenders, and clingy trim. If the route forces you into a tight squeeze, you may choose to backtrack and re-route rather than press forward into a situation where paint, chrome, or plastic trim would bear the brunt of a misstep. Staying on well-traveled routes reduces the chance of encountering debris that isn’t clearly visible from the driver’s seat. Those routes are more likely to have been cleared and maintained, which translates into fewer surprises and fewer scrapes on the rocker, the side panels, or the roofline.

Planning your journey is as important as the drive itself. Before you even leave base camp, sketch a rough plan that accounts for weather, daylight, and the possibility of trail closures. If you’re traveling with a crew, establish a clear plan for spotting hazards and communicating line choices. The more you know about the terrain before you start, the less you have to improvise when you’re out there. This discipline aligns with other preventive measures discussed earlier in the guide, such as pre-trip checks and carrying protective gear. A well-planned route isn’t a guarantee against every scrape, but it significantly tilts the odds in your favor and preserves the truck’s finish for longer adventures. As you gain experience, you’ll begin to recognize which trail segments consistently yield fewer obstacles and which sections demand a slower, more deliberate pace. This experiential knowledge becomes a valuable asset, letting you anticipate trouble and choose safety without sacrificing the thrill of exploration.

Even with careful route selection, a solid foundation in vehicle maintenance remains useful. A practical touchstone is to couple route choices with a basic understanding of how your truck’s systems interact with rough terrain. For drivers who want to deepen that knowledge, a guided exploration of fundamentals—how the engine, drivetrain, and suspension respond under load and impact—can be empowering when you face uncertain trails. See Mastering diesel mechanics: Your Step-by-Step Path to Success for broader technical grounding that complements your on-trail decisions. The link serves as a resource for developing a working intuition about how your powertrain and chassis behave when the surface bites under the tires, which in turn informs smarter route choices and smoother landings over unavoidable obstacles. Mastering diesel mechanics: Your Step-by-Step Path to Success.

As you weigh your options, remember that route choice is a form of protective strategy. It isn’t about avoiding adventure; it’s about harmonizing ambition with sensible risk management. The trail should invite progression, not invite forced contact. Your mindset matters as much as your gear. When you commit to a route that respects the vehicle’s limits and the terrain’s realities, you’ll often find you can preserve a pristine exterior while still enjoying the challenge of a rugged landscape. The goal is to arrive at each bend with control, confidence, and a clean finish—ready for the next leg of the journey.

For formal guidance on safety and best practices on off-road routes, refer to official resources that ground these practices in established standards. Official pointers emphasize planning, cautious driving, and awareness of terrain as the foundation for minimizing damage while enjoying the adventure. For authoritative safety guidance, see the U.S. Department of Transportation’s off-road tips: https://www.dot.gov.

Shielded Trails: A Cohesive Strategy to Guard Your Truck from Scratches on Off-Road Trails

Off-roading tests more than power and suspension; it tests judgment, balance, and the care you invest in your truck before, during, and after the trail. Scratches happen when metal meets rock, when paint meets dust, or when a branch brushes a door edge at just the wrong moment. A cohesive strategy treats protection as an integrated system rather than a patchwork of quick fixes. It begins with preparation, flows through disciplined driving, and ends with maintenance that keeps your protection intact for the next expedition. When this approach is in place, every rocky pass, root-strewn ascent, and sandy descent becomes a controlled interaction rather than a sudden boundary you could have avoided. The core idea is straightforward: build a defensive layer around the most vulnerable areas, move with thought as terrain changes, and restore the shield after every outing so it remains strong for the long haul.

Protective coverings and armor form the front line of defense. A well-considered setup includes full-body protection options like underbody armor and rock sliders, chosen not merely for their look but for their ability to deflect impacts from rocks, stumps, and buried obstacles. These components should be robust enough to resist repeated scrapes and small impacts while still allowing for field maintenance and inspection. Equally important is a high-quality paint protection film applied over the most exposed zones—bumper edges, fenders, door edges, and other high-traffic contact points. The film is a clear shield that resists rock chips and UV fading, preserving color, gloss, and resale value without altering the vehicle’s silhouette. The aim is to keep the integrity of the sheet metal intact even when the trail tests patience and precision. The choice of material matters, too: steel and reinforced aluminum offer different trade-offs between weight, rigidity, and corrosion resistance. The right balance depends on how aggressively you pursue rough terrain and how much additional protection your truck can carry without compromising handling.

Preparation extends beyond skins and shields. A thorough pre-trip inspection is essential, not only for safety but for preventing incidental contact from turning into damage. Before you roll away, walk around the truck and secure anything that might catch on obstacles: loose trim, brackets, or exposed attachments can become snag points. Check that lights are functional and, if your rig rides through harsh terrain, consider rugged light covers to guard against impacts that might otherwise dim a trip’s mood and your visibility. It’s a simple ritual, but it pays dividends by eliminating surprises on the trail—the kind that can force abrupt maneuvers and unwanted contact with rocks or branches.

Route selection then becomes a matter of prudence and intention. The best way to avoid scratches is to steer clear of the areas where the trail itself fights the vehicle. Stick to designated paths when possible, and anticipate the terrain ahead rather than reacting to it at the last moment. Off-road mapping and planning tools can help you chart routes that minimize dense brush, sharp rocks, or narrow corridors where contact is almost guaranteed. The discipline to slow down in tight sections, especially where overhanging branches might graze the roof or sides, is often more effective than any shield. In wooded or rock-strewn segments, the goal is to reduce momentum, not merely to endure it; a measured pace gives you time to choose the least risky line and adjust your approach angle before contact becomes a fact of life.

Driving technique is where control proves itself. A cautious speed undercuts the instinct to hammer through obstacles with brute force. When facing a log, a rock, or a sudden drop, aim for a deliberate angle rather than a direct hit. This reduces the surface area exposed to a potential scrape and shifts the contact away from delicate edges toward sturdier, structural zones. Staying off the throttle through uncertain sections helps keep the tires in contact with the ground rather than lifting and jolting the chassis. Use low-range gearing on steep climbs or descents to maintain traction and keep the drive smooth. The objective is not to conquer every obstacle at speed but to negotiate it with consistency, preserving both paint and alignment while maintaining a respectful distance from fixed objects like trees, boulders, or hard edges.

Protective planning also incorporates practical, sometimes temporary, measures for quick protection in the field. Fender flares and body guards can extend protection to the wheel arches and lower body panels, reducing the chance of spray and fling from rocks and debris. For short trips or unpredictable detours, lightweight, removable tape or protective film can cover vulnerable areas while you assess conditions or complete an extra leg of a journey. While these measures are not substitutes for fixed protection, they offer a flexible hedge against unexpected scrapes when the terrain is uncertain and the clock is tight. The overarching theme remains: prevention through proper equipment and disciplined execution, then rapid assessment and maintenance once you return to civilization.

After the last mile of a gnarly route, the job shifts to post-trip care. Clean the truck promptly to remove mud, sand, and corrosive residues that can wear down finishes or contribute to rust. Mud and grit trapped in seams, under skirts, or in the undercarriage can cause micro-scratches and long-term corrosion if left untreated. A thorough rinse followed by a gentle drying helps reveal any new imperfections that require attention. Careful inspection should focus on edges, fasteners, and protective coatings: look for lifted film, peeled edges, or areas where the armor has viscerally shown signs of stress. If the paint protection film or other guards show wear, arrange for professional evaluation and renewal. Protection is not a one-and-done purchase; it’s a system that benefits from periodic checks and timely refreshment to maintain its effectiveness over many adventures.

A cohesive protection strategy also recognizes the value of ongoing maintenance as part of the off-road lifestyle. Vehicles that see rugged use benefit from routine improvements in both technique and equipment. Periodic touch-ups, reapplication of protective films, and adjustments to armor components help to sustain the barrier between metal and the trail. The most effective protection remains invisible to the casual observer: it lives in the quiet refusal to take unnecessary risks, the deliberate choice of lines, and the insistence on a measured pace that prioritizes longevity over the thrill of speed. In this way, protection becomes a habit as much as a hardware choice, a mindset that keeps the truck looking as good on day one after the trip as it does on the showroom floor.

For readers seeking a deeper, hands-on maintenance mindset, consider exploring practical guides focused on vehicle upkeep and repair. The field manual approach to maintenance emphasizes understanding how components wear together and how to approach a repair with a calm, methodical plan. This mindset aligns with the protective philosophy described here and reinforces the notion that protection is as much about how you treat your truck after the trail as about what you install before you hit the trail. To complement this approach, thoughtful maintenance practices can be reinforced through one practical reference: diesel mechanics guide, which offers a structured framework for diagnosing issues, performing routine service, and sustaining off-road readiness over time.

In sum, the path to scratch resistance on rough trails is not a single upgrade or a single route choice. It is a deliberate, integrated workflow that blends protective hardware, meticulous pre-trip checks, wise route selection, controlled driving, and diligent post-trip care. The result is a truck that can endure the worst a trail can throw at it while maintaining its appearance and structural integrity. When you commit to this unified approach, the line between challenge and capability becomes a matter of planning, restraint, and care rather than chance. And with ongoing maintenance as part of the routine, your off-road truck remains ready for the next horizon, rather than a project that waits for a quiet day to be repaired.

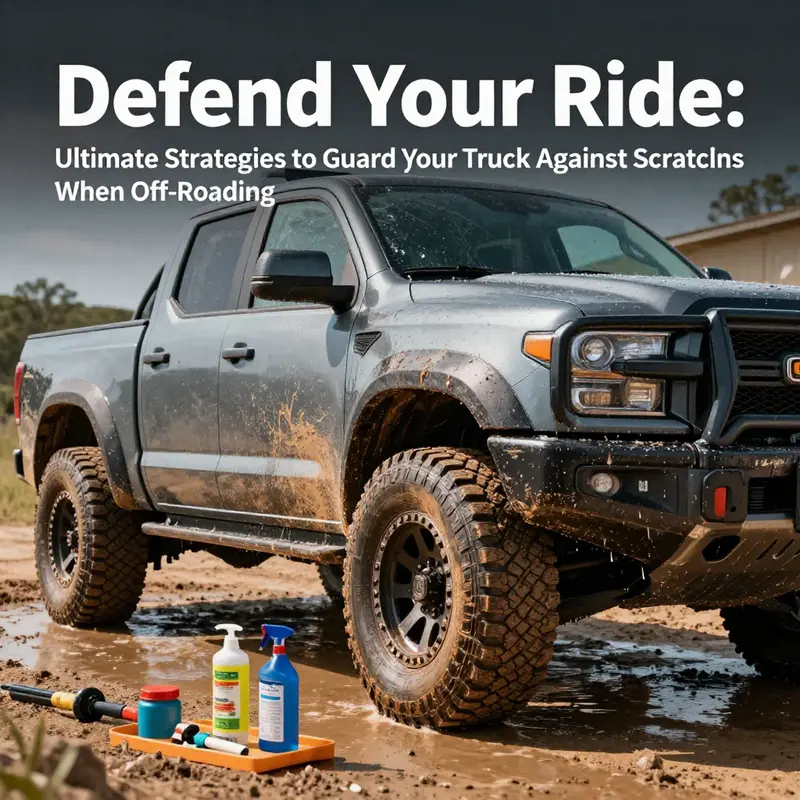

Scratch-Proof After the Trail: Post-Run Maintenance That Keeps Your Truck Looking Pristine

When you return from a rugged run, the trail doesn’t just leave a memory on your tires; it leaves a fingerprint on your paint, trim, and undercarriage. Scratches can come from a stray rock kicked up by a tire, mud dried into seams, or a branch snagging along a rock-grooved fender. The most effective defense is a calm, methodical routine that treats post-run care as an essential part of your off-road experience, not an afterthought. Start with a thorough, deliberate cleaning that targets the areas most exposed to damage: the undercarriage, wheels, fenders, and the lower doors where grit tends to collect. A high-pressure washer can do a lot of the heavy lifting, but you must use it with care. Focus on angles rather than blasting in a straight line, and keep the wand at a safe distance to avoid shocking seals or blasting water into electrical connections. The goal is to loosen and remove embedded grime, not to force it into crevices where it can harden into a future scratch or corrosion hotspot. If a component is particularly delicate—sensor housings, boot grommets, exposed wiring harnesses—treat it with a gentler approach or skip direct high-pressure contact altogether. A careful, patient rinse will pay off later by making waxes and sealants work more effectively while reducing the likelihood of microabrasions that wander from “minor” to “noticeable” over time. The same mindset applies when you hand-wash or spot-clean sections that see the most abuse during a trail—rock chips and mud margins around the fender lips, the rocker panels, and the trailing edges of the doors. In short, the post-run ritual begins with cleaning, but it builds into a broader strategy for preserving the finish and the overall integrity of the sheet metal.

After you’ve cleaned the surface, switch your attention to inspection. A careful once-over of the body panels, bumpers, and side mirrors can catch dents, loose trim, or chips that might otherwise go unnoticed until they threaten the paint layer. Small dents can become focal points for stress cracking if they’re left unaddressed, and loose trim can vibrate loose again on the next outing. Pay special attention to the edges of panels where debris is likely to lodge during a wash. If you see anything suspect, address it promptly, whether that means reseating a trim piece, tightening a fastener, or flagging a damaged area for professional service. This is not about overreacting to every blemish, but about building a habit of early detection that keeps minor issues from becoming costly repairs.

When it comes to protective measures after a trail, the practical rule is to layer protection in a way that supports the finish rather than relying on a single solution. A fresh coat of wax or a durable sealant creates a slick barrier that helps shed mud and debris before it can scratch or cling to paint. This barrier is especially valuable on doors, hood edges, and bumper contours where contact with brush, gravel, or grit is most likely. If you’re a frequent off-roader, consider painting protection film (a clear, durable layer) on the high-risk zones such as the leading edges of the hood, lower rockers, and the front bumper. This film acts as a sacrificial shield, taking the brunt of minor impacts and rock strikes so the underlying paint endures. For readers seeking hands-on, mechanics-focused guidance on post-run maintenance and scratch prevention, there is a practical resource worth exploring: a detailed diesel maintenance guide that offers insights into mechanical checks and protective care that translate well to off-road wear. It’s worth reviewing for a deeper understanding of how mechanical systems interact with rugged use and how proper care can prevent cascading issues after a trail.

Beyond cosmetic protection, don’t overlook fasteners and components that can loosen from the vibrations of rough terrain. During a post-run inspection, check that all visible bolts, brackets, and suspension components are snug and in good condition. A loose bolt or shifting bracket can create a new source of noise, alignment change, or even a safety hazard. If you find anything out of the ordinary, address it promptly. Tightening fasteners to the manufacturer’s specified torque is a straightforward, preventive step that pays dividends across many off-road scenarios. A careful review of the undercarriage can also reveal rock strikes, bent or displaced trim, or early signs of rubbing between a tire and fender. Correcting these issues after a trail reduces the risk of ongoing abrasion and helps your protective layers do their job more effectively. The goal is to maintain a clean, well-protected surface that resists the accumulation of abrasive grit and reduces the likelihood of micro-scratches that accumulate with each outing.

The long game of post-off-road maintenance is consistency. A reliable schedule—wash, inspect, seal or re-film, check fasteners, and re-treat high-wear areas—creates a predictable cycle that extends the life of the finish and the structural components alike. If you opt for protective film, remember that film requires periodic inspection for edge lifting, wear at vulnerable corners, or microtears that can propagate if ignored. Films do not eliminate the need for regular washing and wax maintenance; they complement rather than replace a broad care routine. Even with protective layers, environmental exposure—sun, acid rain, salt in winter, and repeated abrasion from brush—can gradually erode protective measures. Consequently, you should reevaluate protection levels each season or after particularly challenging trails, ensuring your approach remains aligned with how aggressively you off-road and how often you tackle harsher terrains.

A practical mindset for post-run care blends the mechanical with the aesthetic. Recognize that scratches are not merely cosmetic nuisances; they can be warning signs of deeper issues in the finish or in fastener integrity. By treating the post-run interval as a stewardship period—carefully cleaning, inspecting, protecting, and tightening—you preserve the vehicle’s value and reliability. And while the specifics of how you apply protection may depend on your climate, vehicle color, and typical routes, the underlying principle remains constant: preparation today prevents repair costs tomorrow. For readers curious about the mechanics of maintenance and a deeper dive into care strategies, the diesel maintenance guide linked earlier provides a complementary perspective on how robust mechanical upkeep intersects with surface protection. It reinforces the idea that the best defense against scratches begins long before the trail and persists after the last wheel spin.

In the end, your truck’s resilience on rough terrain is built through a disciplined, repeatable routine that respects the trail’s harsh realities while defending the finish you value. The post-run moment is more than a wash—it’s a strategic pause to assess, protect, and recommit to a plan that keeps scratches at bay and your truck looking pristine mile after mile. For readers seeking broader, field-tested perspectives on off-road maintenance and scratch prevention, a comprehensive external reference offers further depth and context to these practices.

External resource: For more detailed guidance on off-road maintenance and scratch prevention, refer to the following external article: 4×4 Australia maintenance tips for protecting your truck from scratches.

Final thoughts

Protecting your truck from scratches while off-roading isn’t just about aesthetics; it’s about preserving the integrity and value of your vehicle. By implementing robust protective measures, conducting thorough inspections, selecting smart routes, driving carefully, and committing to ongoing maintenance, you can enjoy your off-road adventures without the fear of damaging your truck. Equip yourself with the right knowledge and tools, and you’ll be ready to tackle the wildest terrains while keeping your truck in pristine condition for years to come.